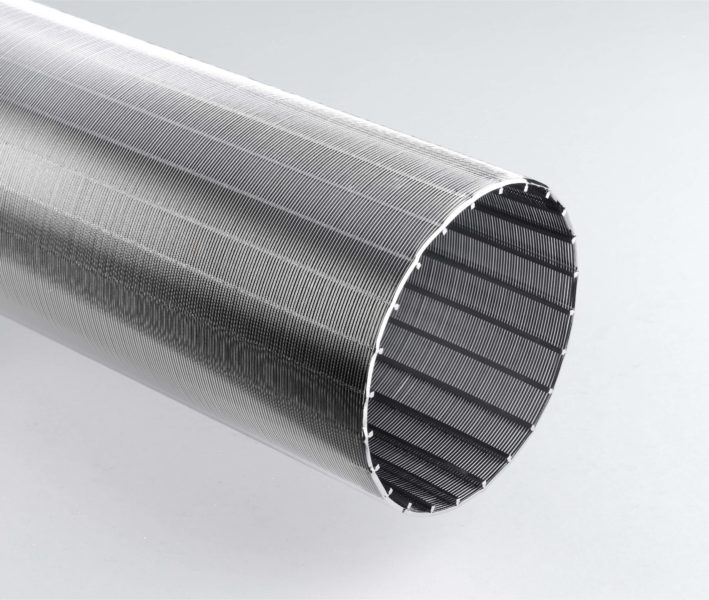

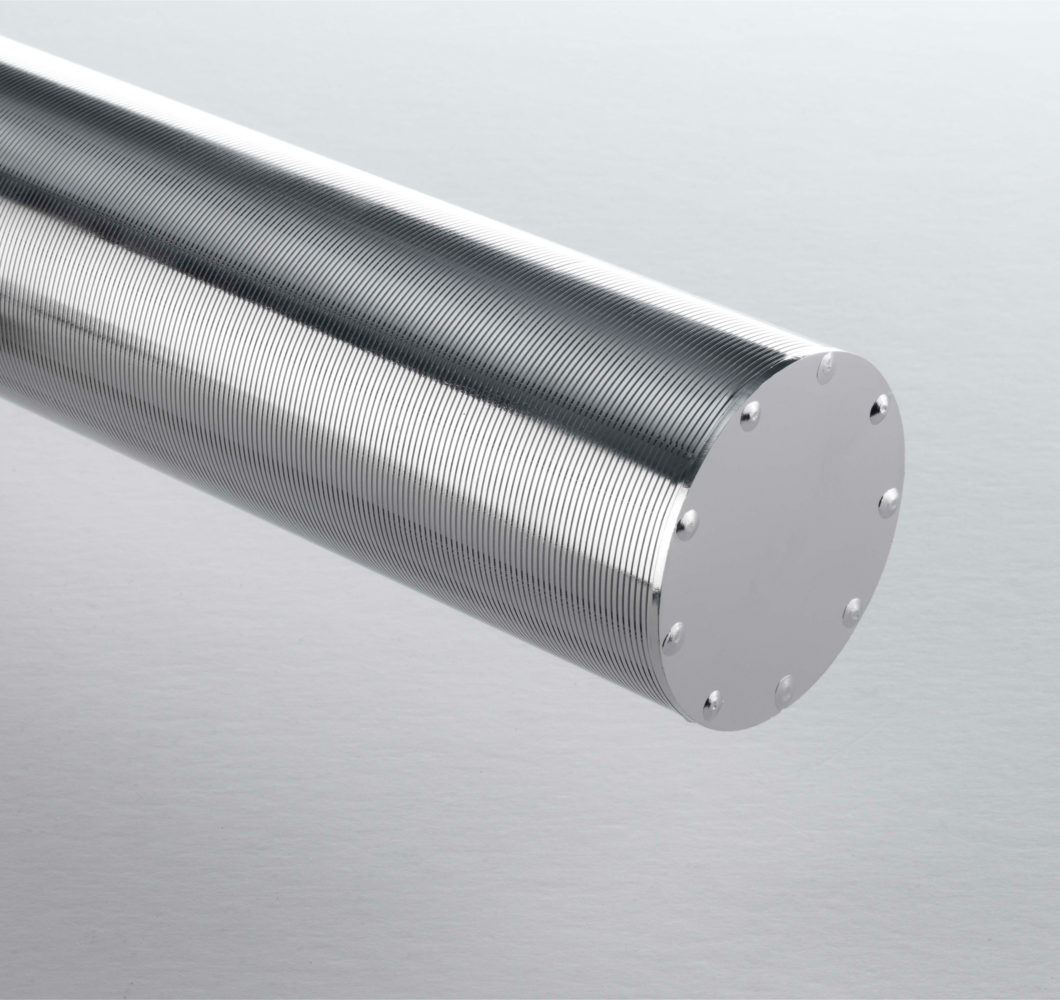

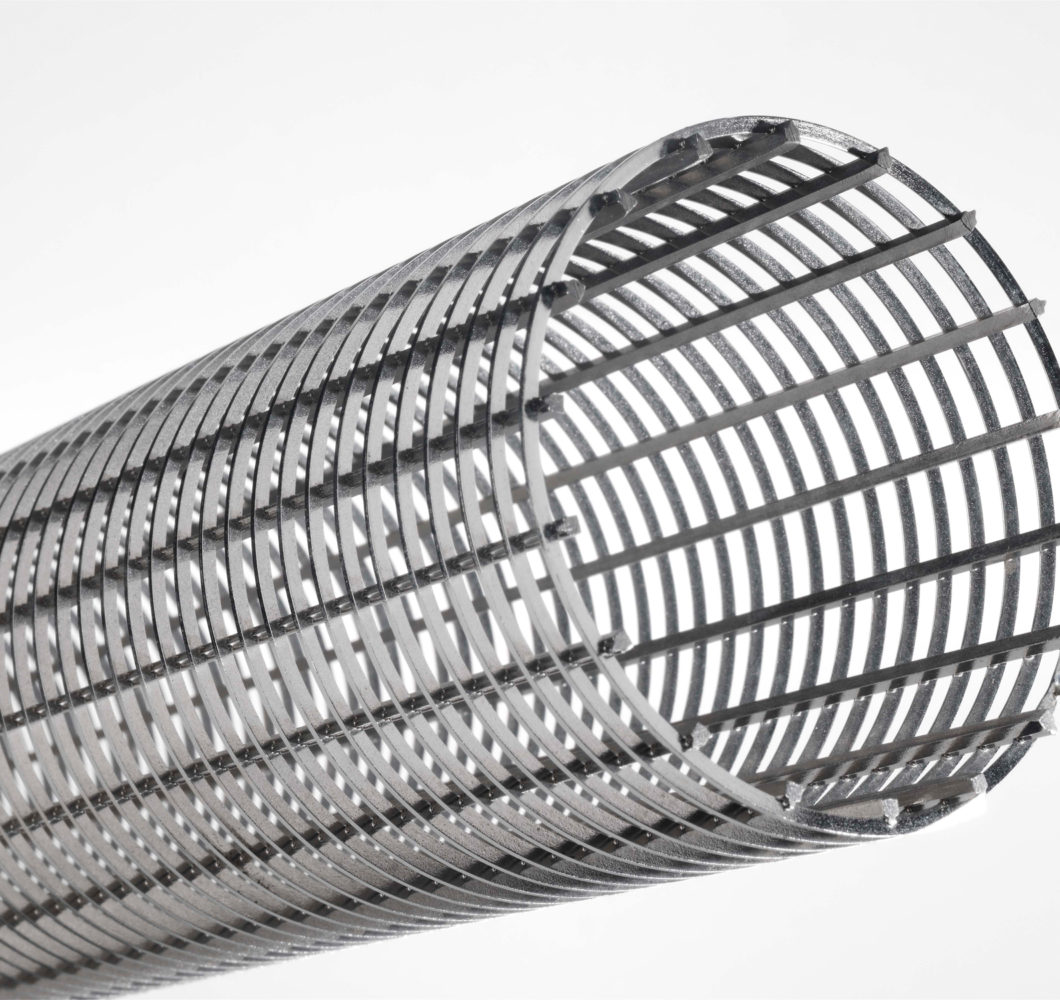

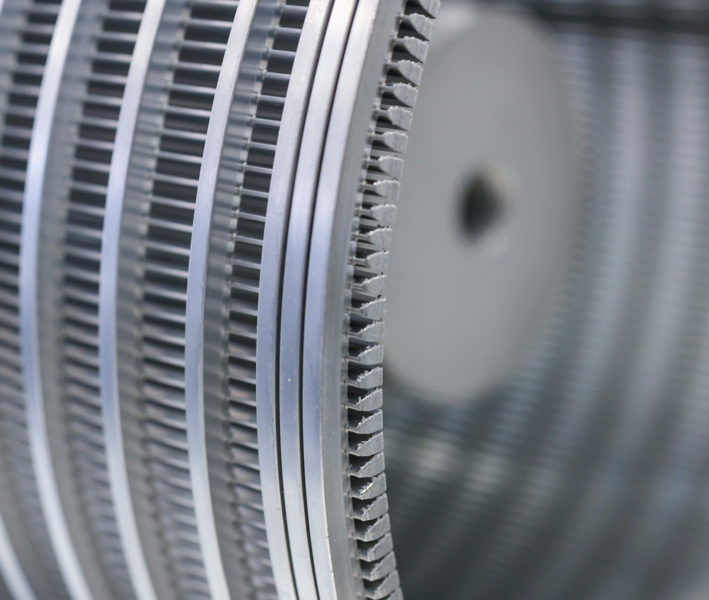

In the axial version the slot-forming profiles run parallel to the longitudinal axis of the wedge wire screen cylinder.

The cross bars are spirally wound around the profile from outside and are resistance-welded, as in the radial slot version. The inside filter surface, i.e. the working surface, is smooth. It is produced either directly as a cylinder or, alternatively, from a plain sieve panel which is then re-rolled. The special feature here is the internal smooth screen area, ideal for cleaning with a stripper.

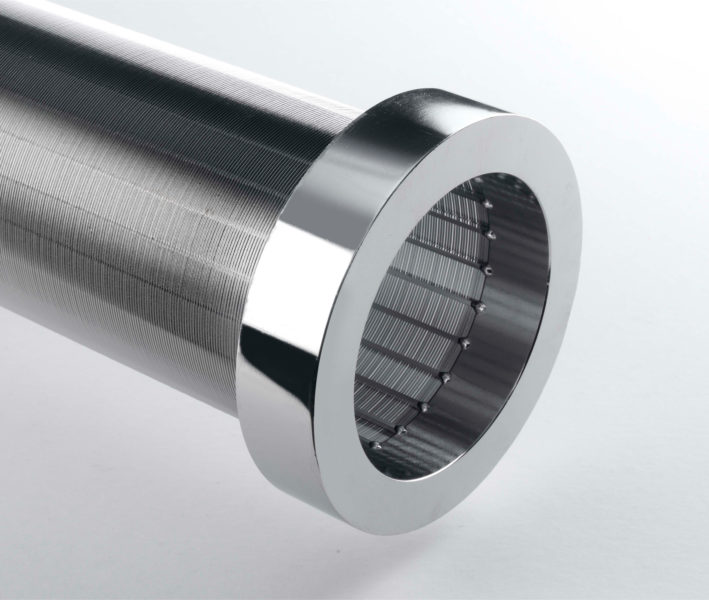

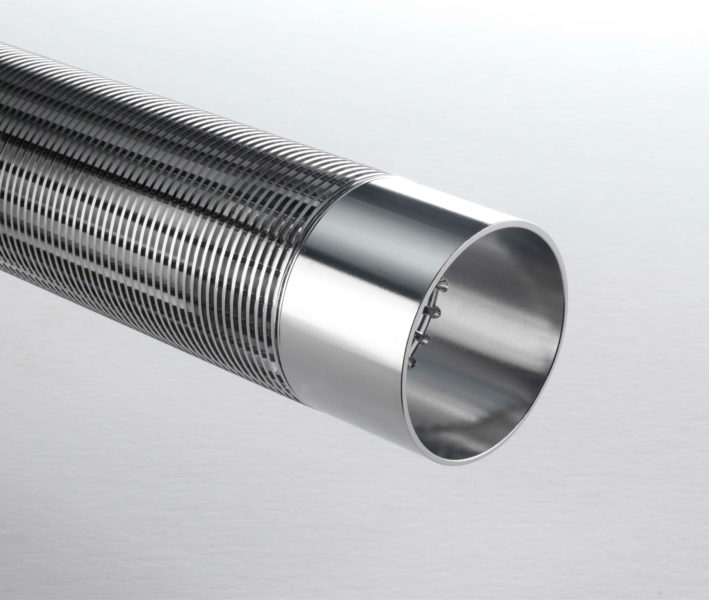

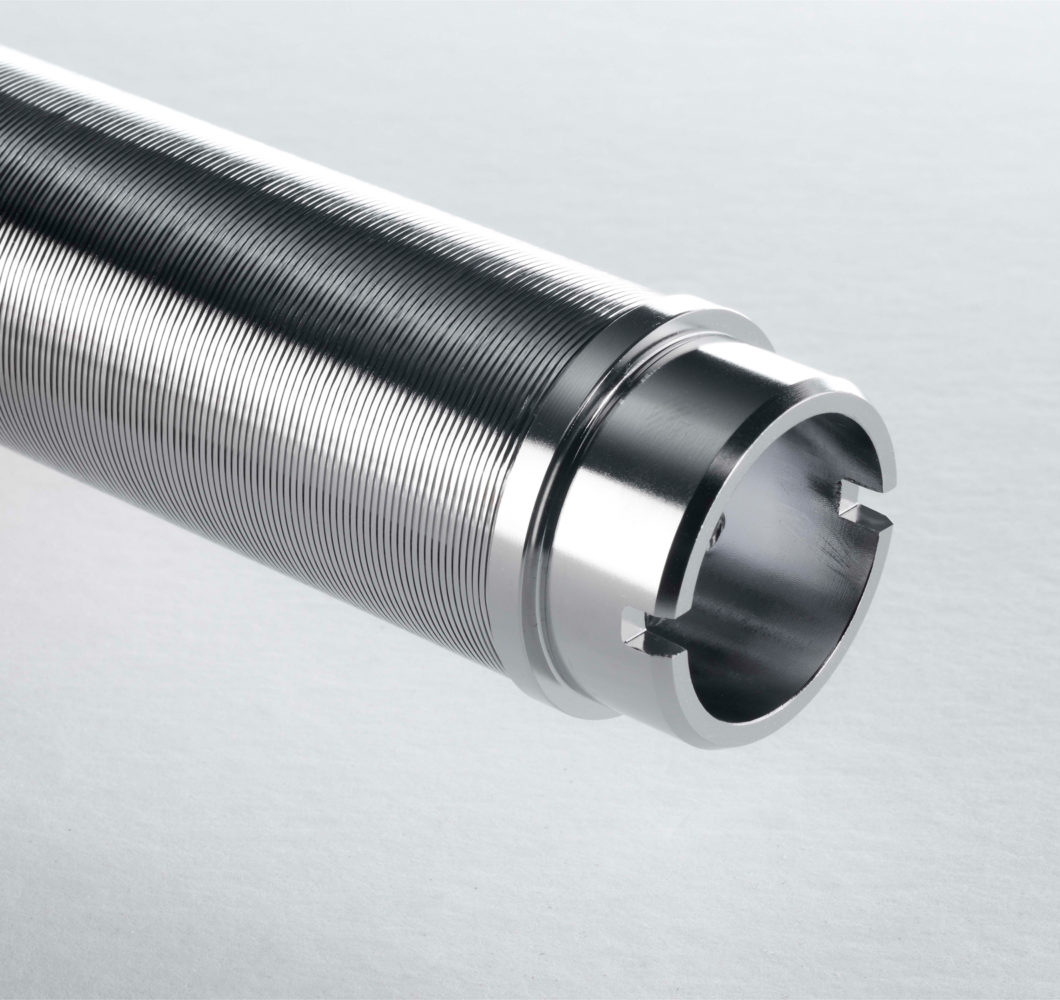

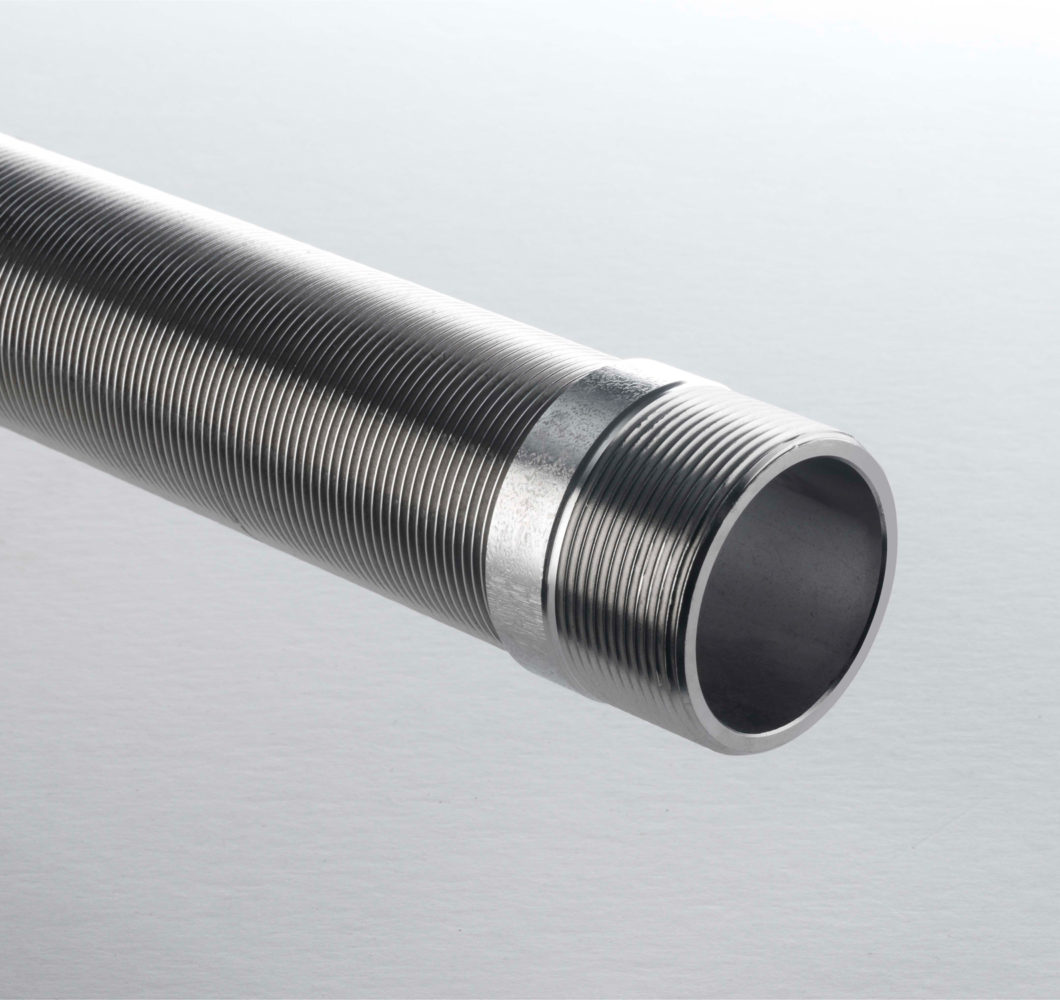

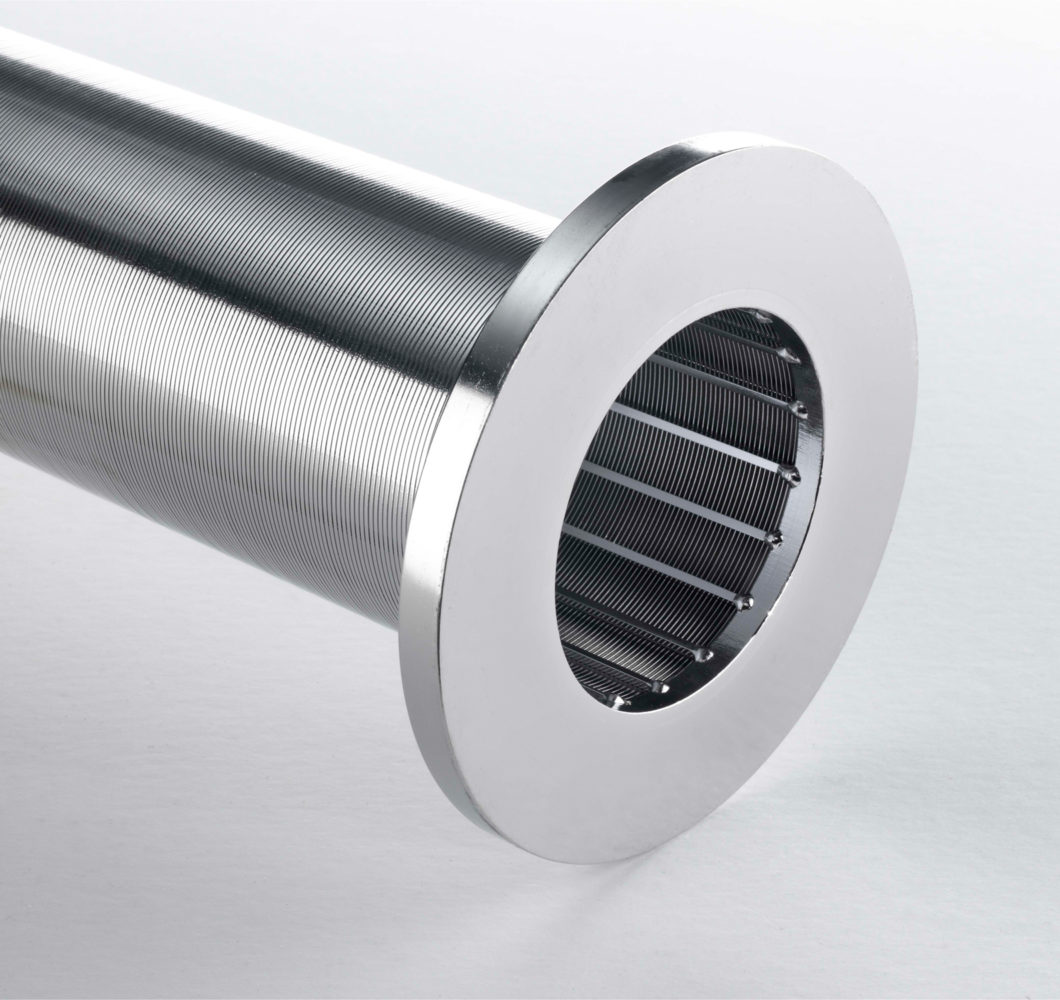

FITO (Filtration Inside to Outside) with working surface inside

The flat sides of the triangular slot performing profiles are welded to the internal cross bars.

The smooth inside working surface is interrupted by the cross bars. Cleaning generally takes place by means of counterpressure flushing.

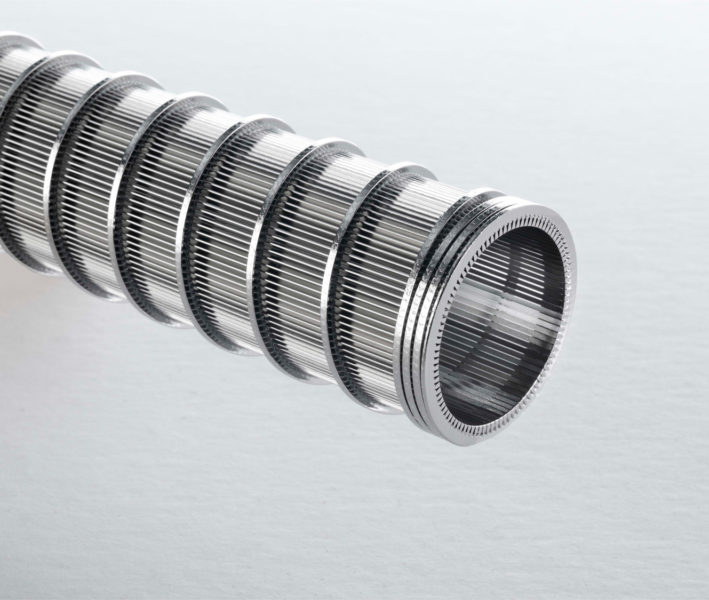

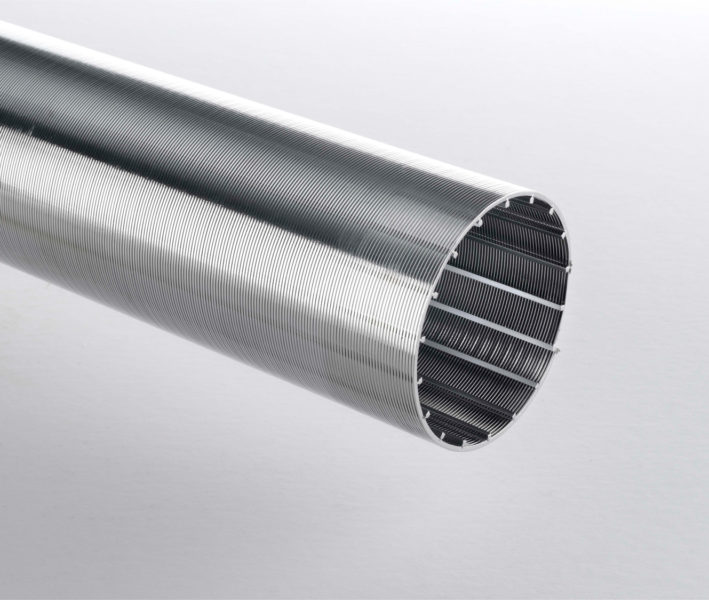

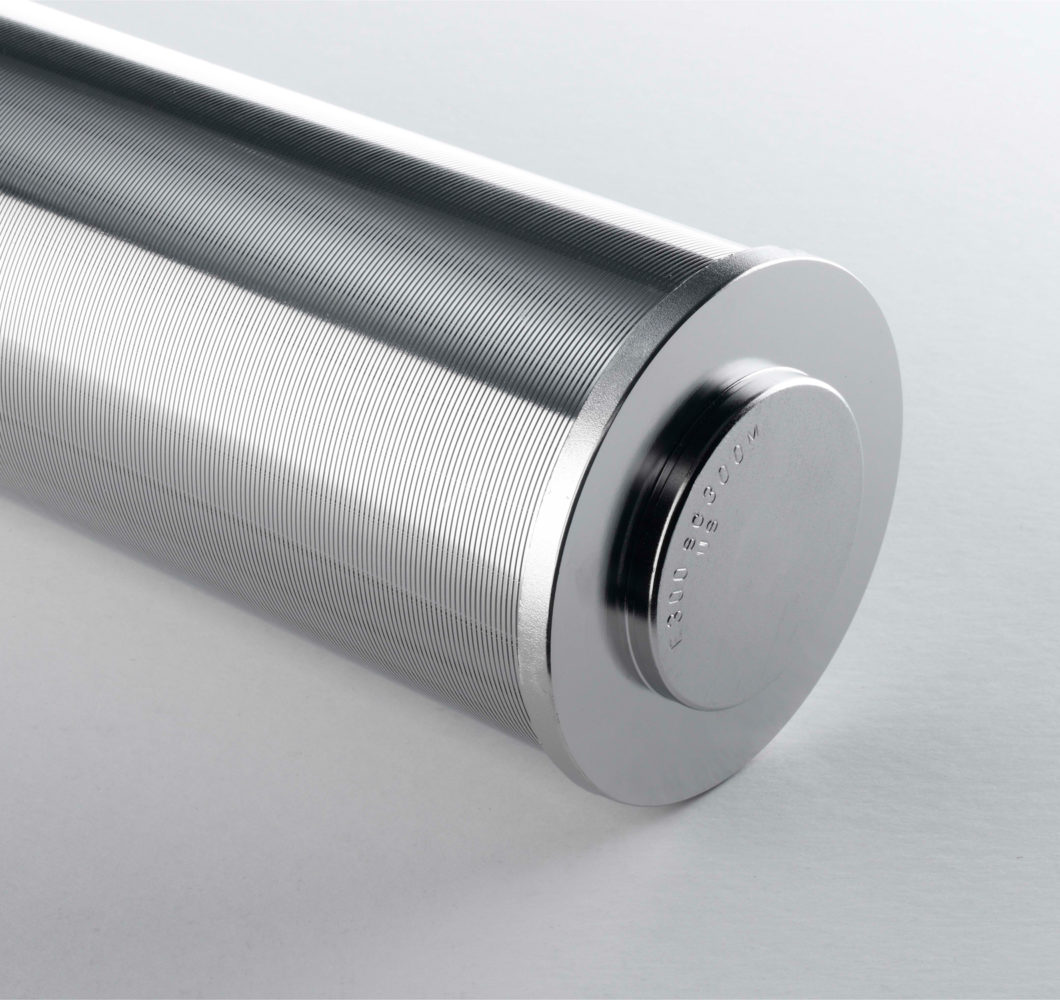

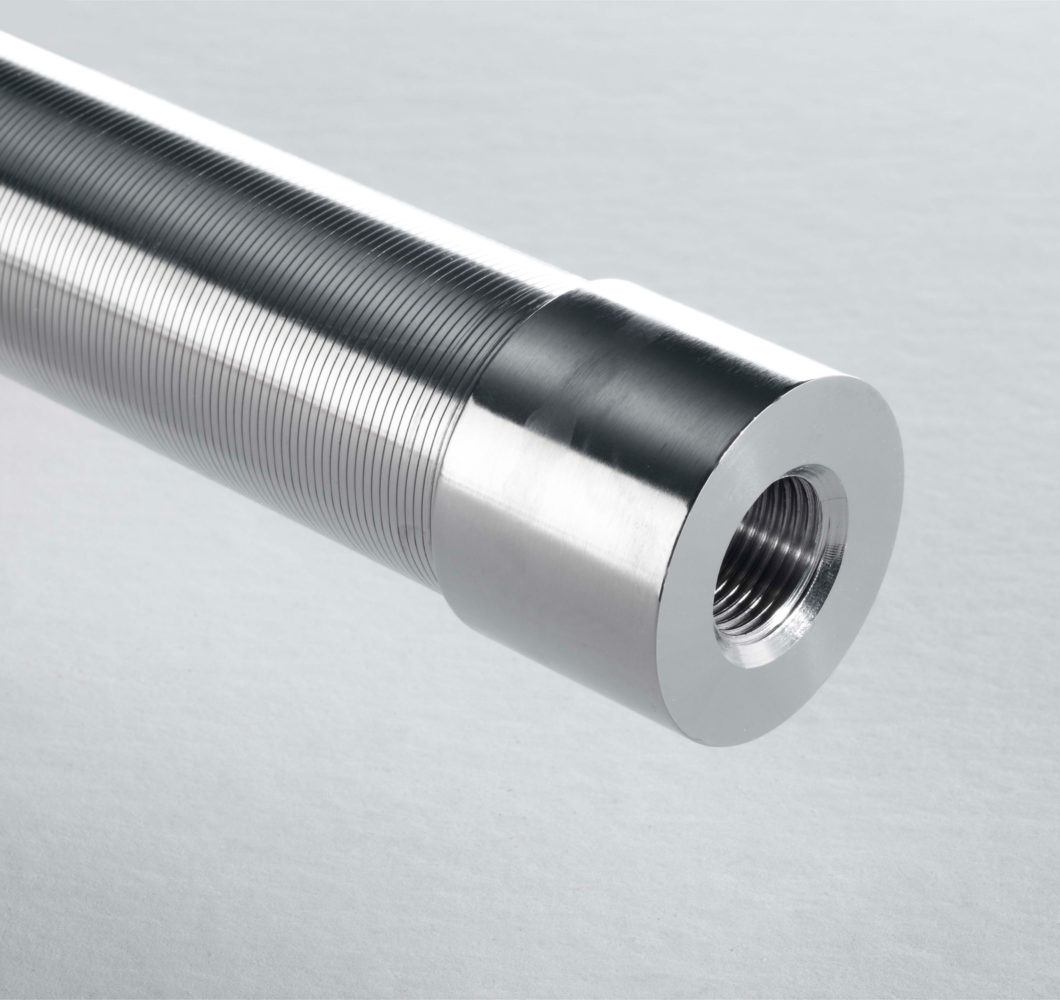

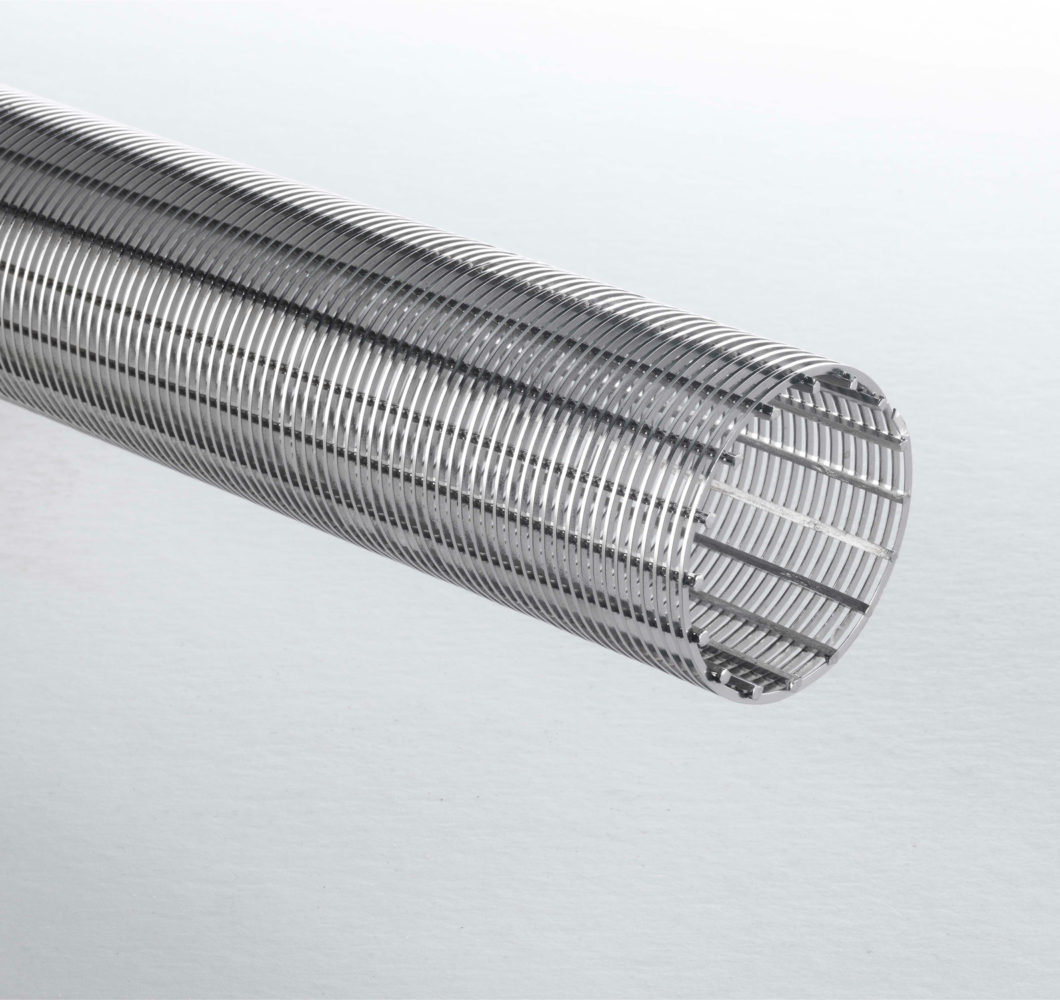

FOTI (Filtration Outside to Inside) with working surface outside

The triangular slot performing profiles are welded to the internal cross bars with the wedge-shaped side on the inside.

In this frequently used design, the outside filter surface, i.e. the working surface, is smooth, which allows potential accumulated solid matter to be cleaned off easily.

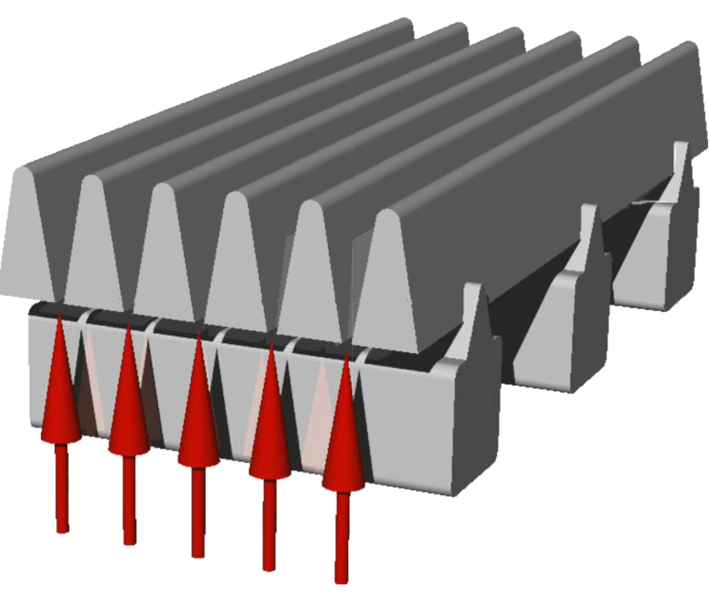

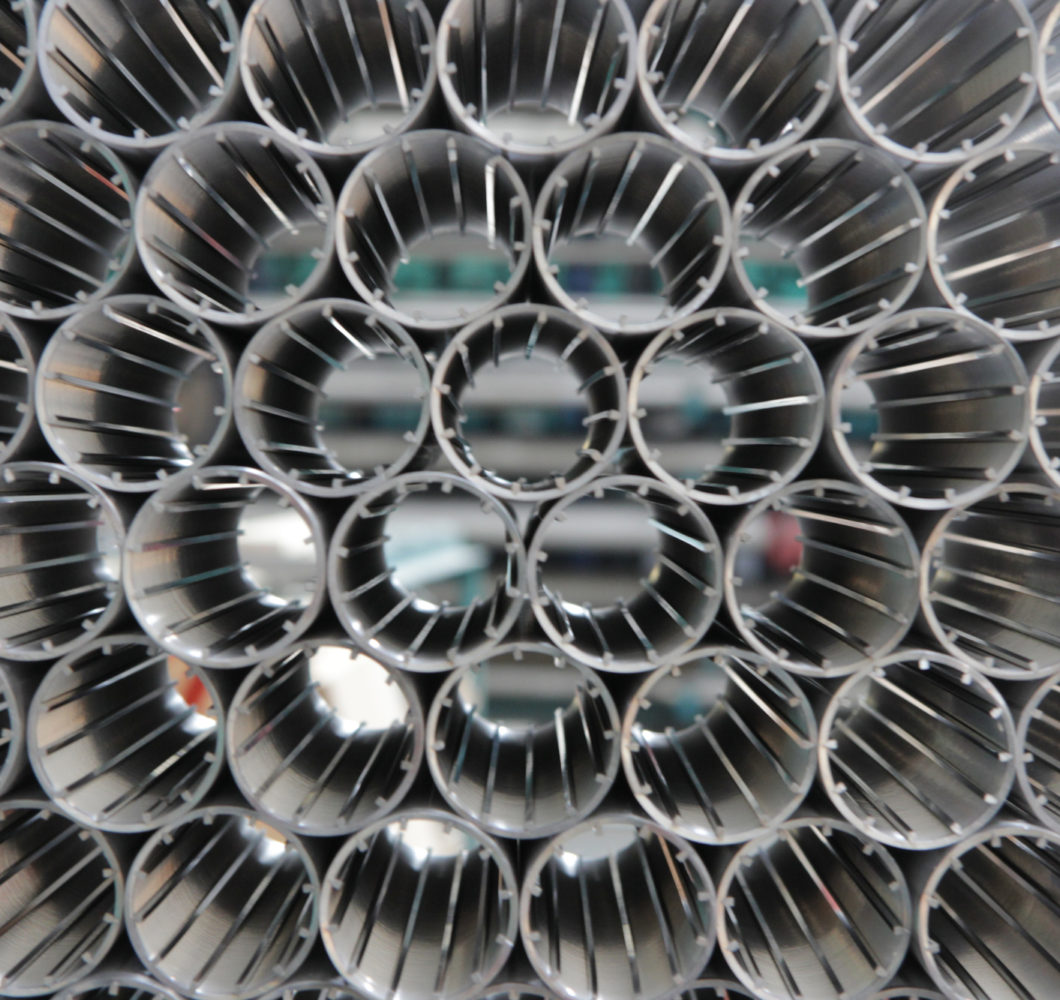

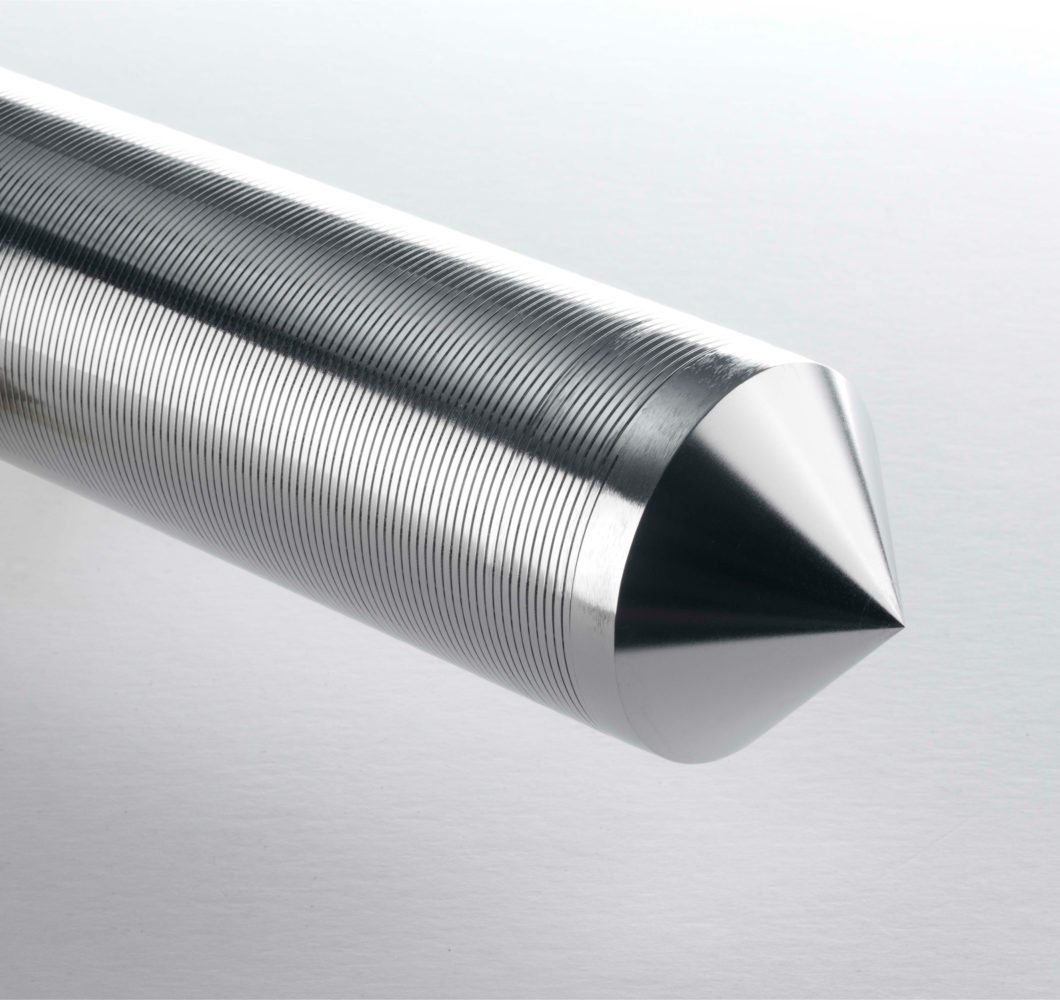

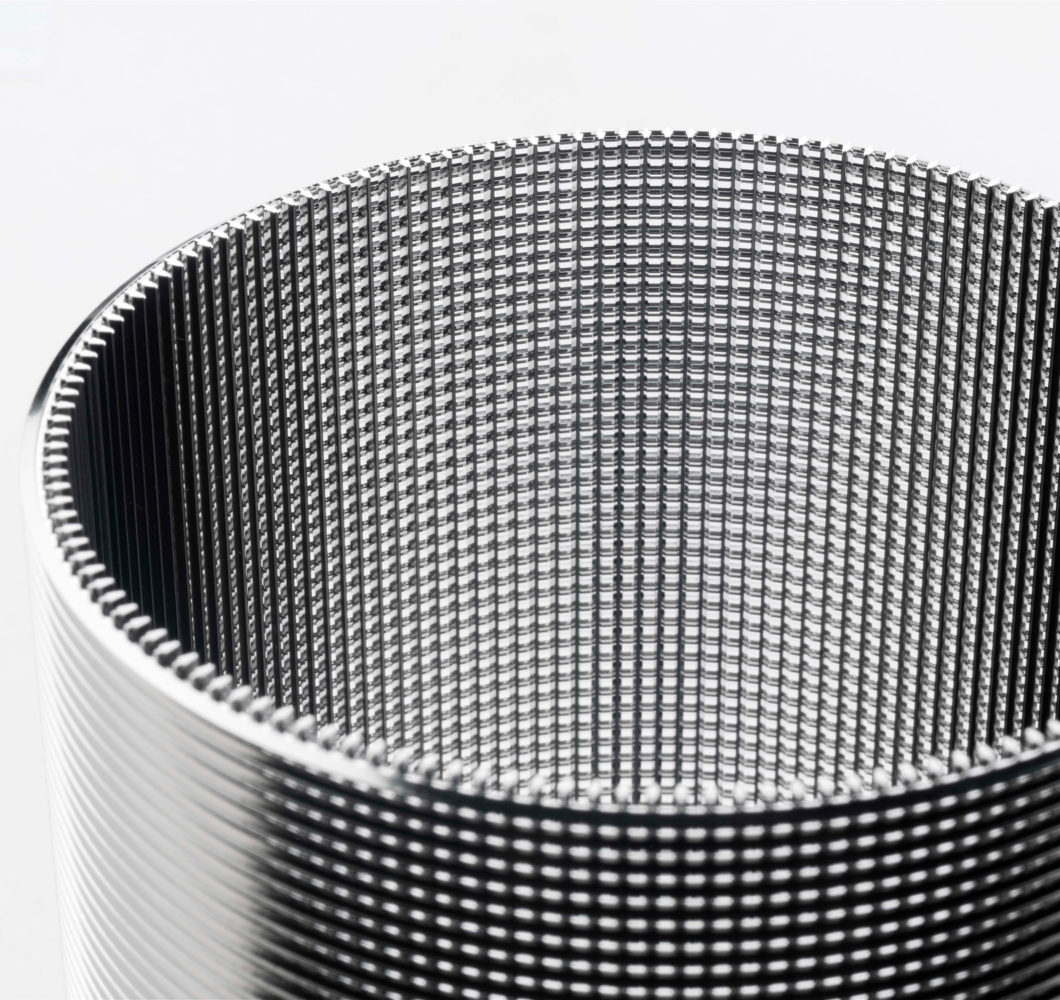

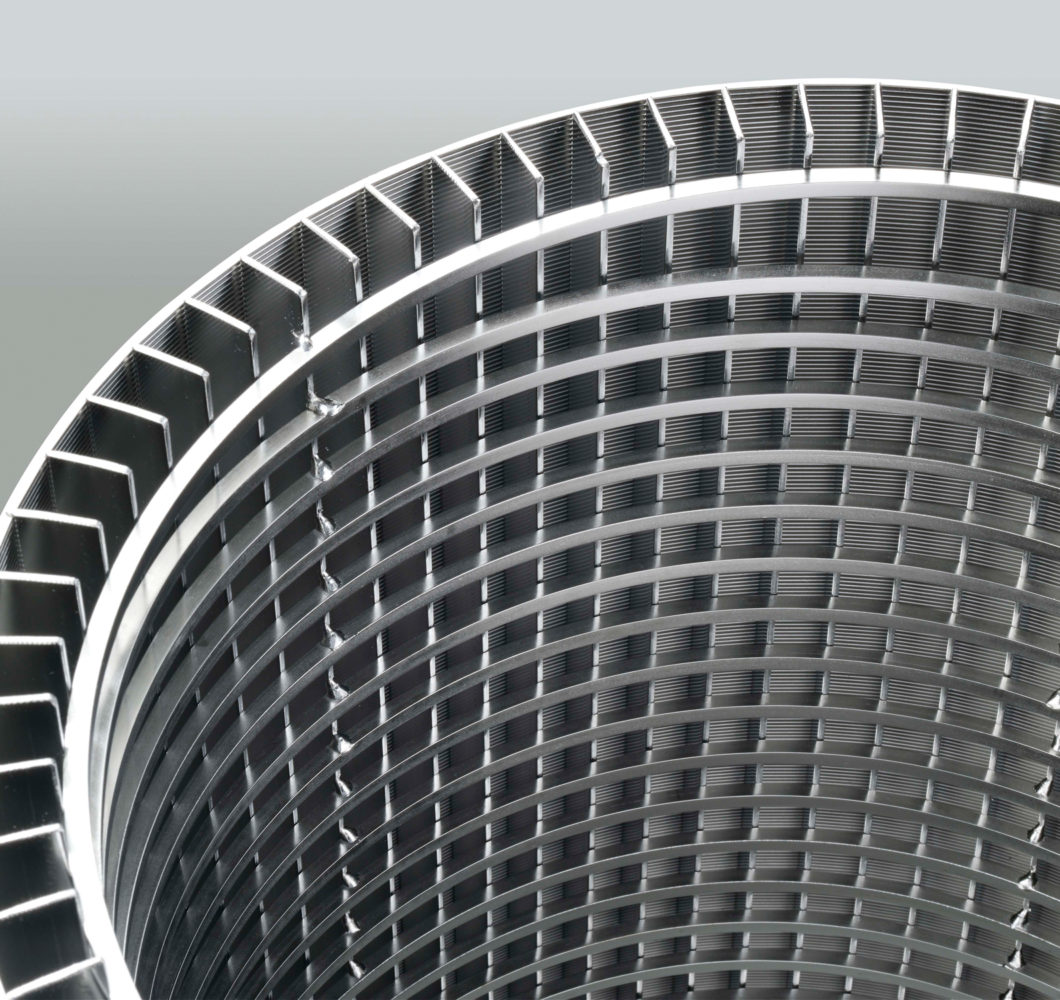

The latest OPTIMA innovation with a square filter aperture adopts a new application concept.

This patented design can, according to preference, be fed from both sides with perfectly positioned radial and axial apertures.

These high-precision filter tubes have advantages particularly for fibrous media. The special profile geometry allows the creation of very small square apertures of up to 50 µm.