We cordially invite you to ACHEMA 2024

Die ACHEMA findet vom 10.-14.06. 2024 in Frankfurt statt - und wir sind dabei! Sichern Sie sich jetzt Ihr kostenloses Ticket für die ACHEMA 2024!

More

An oven belt has the task of transporting the baking media in a continuous process through the oven, so that at the oven’s end the baking process is finished, which basically allows for reduction of humidity. Contrary to baking in rack ovens, there is no interruption when charging and discharging the oven.

Tunnel ovens are varying in length from very small (~20 m) up to really big (>~120 m).

Also with regard to the oven width there is a great variety starting from ~500 mm up to 1800 mm (for biscuits, crackers and cookies).

Materialwise the belts are usually made of non-stainless steel grades. Applications for the use of stainless steel belts are rare.

The belts used in baking tunnel ovens are not “guided” by chain systems etc., but are free running. As a consequence there are certain requirements to be met with regard to straightness, dimensions and regularity (when it comes to mesh belts).

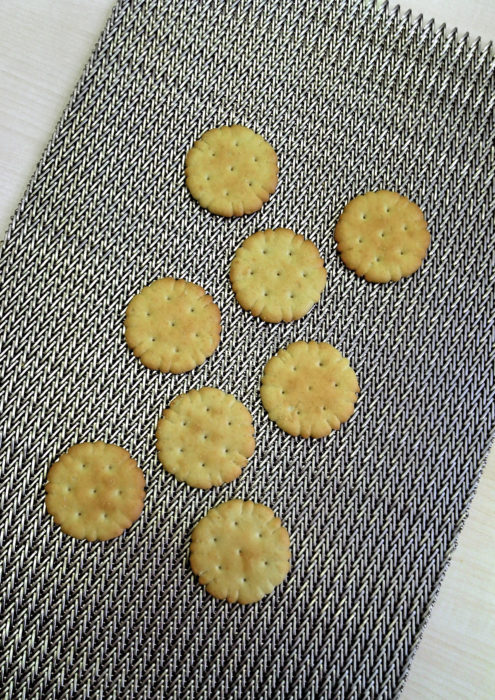

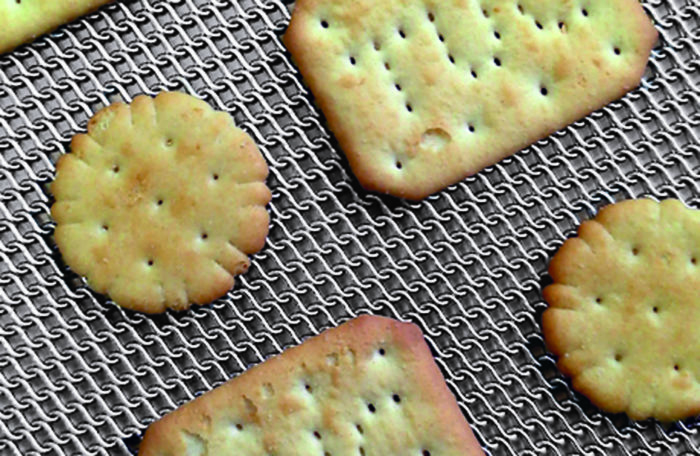

The belt is a carrier medium for getting the product through the oven continuously and evenly. The intention of the use of any belt is, that it should not have any negative effects for the baking and possibly even improves the process.

Next let’s have a short look at the technical features of all types of belts that are currently used in tunnel ovens.

Doing so, I would like to draw your attention also to an earlier article ‘Biscuit Oven Conveyor Bands’ published here in Techtalks in January 15, written by Iain Davidson

As a preface please bear in mind that choosing a belt type is not always based on “hard facts”, but often influenced by tradition, experience, availability, knowledge, technical education background, price, commercial necessities and trade restrictions.

1.Solid & perforated steel belts

These belts are made of solid or perforated carbon steel sheets varying in thickness between 1,0 and 1,4 mm (with a weight of ~8 to 11,2 kg/sqm). For a product with a liquid dough and a high humidity contents, that requires baking by conduction, there is mostly no way around this type of belt.

It is the belt type with the highest price. It can only be installed by skilled (external) personnel. Repairs are difficult. Driving and turning drums in ovens with this belt are usually smaller than the belt width and the drums are convex.

Properly installed and maintained a long life time can be expected.

2.Multiple spiral belts, a.k.a. “CB”-belts

These are very tightly woven and heavy weight wire mesh belts with a comparatively smooth surface with 2-5 crossbars (a.k.a. connertors) placed in each spiral wire.

Their ideal use is for products like American or soda crackers with a high humidity contents, where the process of conduction baking requires a very high heat storage capability.

CB5 and CB3 are typical brand names for these types of belt.

Because of their high weight (easily >20 kg/sqm) they have a considerable impact on the energy consumption, the drive and support structure of the oven.

Also because of the weight these belts are often and mainly supplied in segments of 10-20 meter, put together on site. So installation of these belts is a “task” with a high risk of damages.

Connecting and repairing is not so easy and requires expertise and experience.

3.Braided link belts

This is a belt with a very simple mesh structure, which consists of spiral wires braided in opposite senses and corrugated crossrods. It is quite a cheap belt and since it can be woven quite densely, it is sometimes used for price reasons as an alternative to the Z-belt. The surface of this belt is however not completely flat, so you don’t get a baked product with a smooth bottom side, which can make packing difficult.

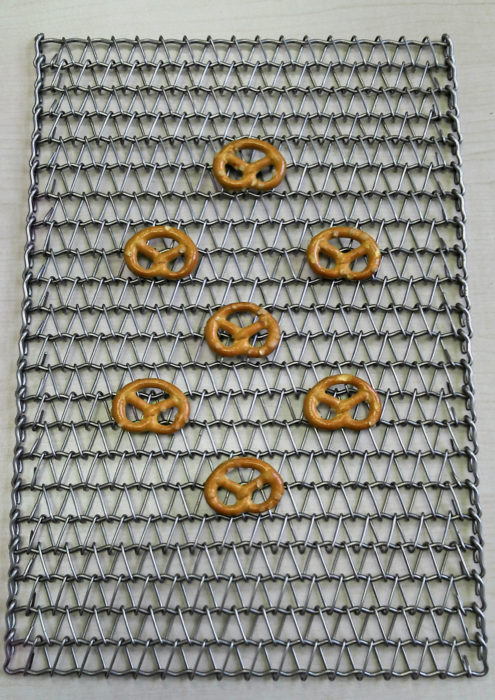

For baking of stix and pretzels, however, this is quite a popular and good belt.

On a sidenote:

Some endusers and OEMs favoured for some time another type of braided link belt without crossbars, where the spiral direction was changed every ~500 mm. An “extremely” open mesh structure was this belt’s advantage. This was however outnumbered negatively by very difficult tracking along with a big length elongation under tensioning

4.Z-belt or Rolled baking oven belt

This rolled baking oven belt is a wire mesh belt, that consists of spiral wires only and has no crossbars. In other types of belts, crossbar are doing the main job in absorbing the tensioning forces under operation. So why no crossbars in a Z-belt? There are 2 reasons:

A) it allows a lower weight, so there is not much energy “lost” for heating the belt itself and not baking the product.

B) it results in a better ratio between “wires and holes” with the result of a better heat circulation in the oven, often speeding up the baking process, but definitely reducing the energy bill.

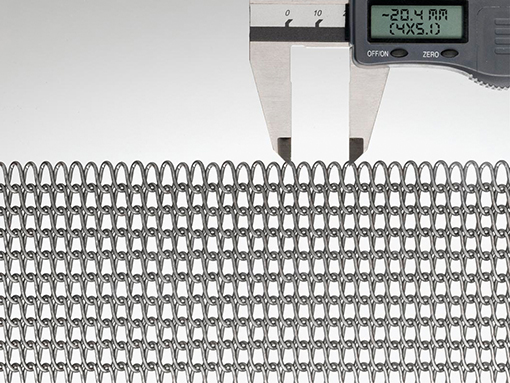

The belt allows the product baking on a smooth surface. However manufacturing of such a belt with spirals only, even rolled flat, is somewhat “tricky”.

The belt structure has to be very regular and equal. Only then the tensioning forces are evenly absorbed over the whole belt width, which is essential for good straight running and easy tracking.

Hence there are not so many producers for such a belt around the world. The 2 main suppliers are in Europe, namely in France and Germany, where the Z-belt or rolled baking oven belt has a long tradition already.

There have been trials by other producers in India, China and for some time ago in Brasil, but their belts had and have their pros and cons.

The Z-belt, with its advantages, has been seeing over the last ~10-15 years an huge increase in popularity, with the increase in different Z-belt types and producible widths it could replace very well many other belt types.

After the description of the various types of bake oven belts let’s highlight their main pros and cons:

Solid and perforated steel belts

pros:

cons:

Multiple spiral belts, a.k.a. “CB”-belts

pros:

cons:

Braided link belts

pros:

cons:

Z-belt / Rolled baking oven belt

pros:

cons:

Before we come to the next section, we should do a little excursion back into the history of tunnel oven belts.

For many decades the “typical” tunnel oven had a length of not more than ~60 m with widths of mainly 800 & 1000 mm. In the 80s bigger ovens with ~1200 mm width and length sometimes up to 80 m started to appear.

A “boom” in baking manufacturing started, when the countries in the Middle and Far East “discovered” crackers, biscuits and cookies as a good tasting enrichment of their daily diet.

This boom was particularly big in the countries with growing high populations in South East Asia. Until recently their diet very much consisted of rice and rice products. However they realized that products made of wheat and rye, could saturate more appetite.

So demand in these countries grew and grew, many bakeries with many tunnel ovens were built and the consequence was to construct bigger ovens with bigger capacities.

Over the last 10-15 years the oven sizes grew and grew. Today 8-9 out of 10 new ovens built have a width of 1200 mm and more. Some OEMs concentrate their production very much on these bigger ovens, even picking 1500 mm as their “standard” and now starting to look for oven of >1700 mm width. And oven length of ~110-120 m has become nothing special these days, where there are ovens under construction, going to a length of ~150 m.

But why these bigger ovens? The relationship between oven width and capacity is a clear one. But why increasing the oven length? The length increase simply allows for a higher baking speed. In “high speed ovens” the belt is running at ~33 meter/min. with a peak baking temperature of ~330 ⁰ C and so another increase of capacity.

As mentioned before, a Z-belt consists of a woven mesh structure, that is rolled flat. The problem is not to produce the mesh structure. The challenge is the regular and equal flat rolling of this mesh. This flat rolling brought limitations to the maximum possible width of a Z-belt (~1450-1500 mm) for many years. And so in the past it was quite normal that one had to choose multiple spiral belts (CB5 or CB3), despite the better characteristics of a Z-belt for the intended application.

And there was another phenomena, geographical “frontiers”. If the engineers at the OEMs or at the endusers have a US-based education, they were practically only aware of the multiple spiral belts, whereas European-based education had hands on experience with the Z-belt.

Until one or two decades ago, the both Americas were more or less a big white spot for the use of Z-belts. But with the sales efforts of Italian OEMs especially in the Latin Americas, this is slowly changing. And even endusers there now explore the advantages and cost savings, when using a Z-belt instead of a multiple spiral belt CB 5 or CB 3.

One of the European Z-belt producers put a lot of efforts and research in increasing the range of Z-belt types for closing the gap to the use of multiple spiral belts, or at least making this gap smaller. And investments were made to produce belts in larger width of now up to 1800 mm.

All this and the worldwide growing fondness for biscuits, cookies, baked durables and the like is presumably the reason for the growing interest and demand in rolled baking oven belts.

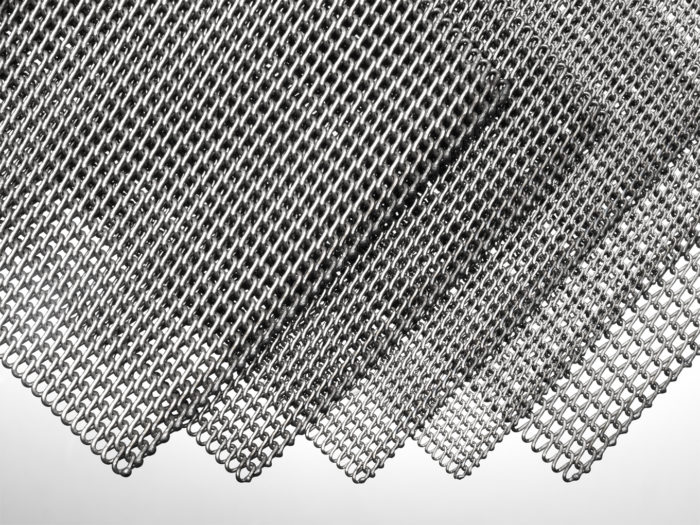

Z-Belts type F4018, F4015, F4012, F2510, F6014 (from left to right)

As said earlier, there are currently two main suppliers for this type of belt and there are clear differences in the product features.

The belts produced in France have looped edges and are composed of segments of ~5 m for the sake of changing the spiral direction with each segment. Also every ~5 m the number of spirals along the width might change. The advantage of the stronger looped edge, which allows – to a certain extent – tracking by vertical rollers is outnumbered by the disadvantages of non-repairability, longer installation time needed and higher tracking support necessity.

The belts from Germany have welded edges, the spiral direction changes with each spiral and a belt length is made of “production units” of ~40-50 m, put together to the final belt length, that non-experts don’t see the connection. The disadvantage of the somewhat weaker welded edge is more than compensated by quicker installation, very good tracking characteristics, repairability and belt straightness. Below I will explain further very much on the range and types of this supplier.

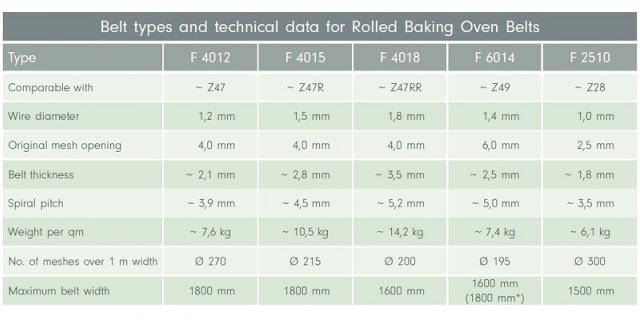

As of today there are 5 different types of Z-belts, all to “answer” to individual requirements from the market.

The popular standard Z-belt F4012 (~Z47)

This is the most frequently used belt type. A good ratio between 1,2 mm wire diameter and ~4 mm mesh opening allows an efficient heat management with good baking results.

The F4012 gives the greatest flexibility both for band width and oven length. However, for belt width of >1500 mm and oven length of >~80 m it is not recommended.

In the past 8 out of 10 belts were a F4012. This has changed with the last decade’s trend for bigger ovens.

The strong & rigid Z-belt F4015 (~Z47R)

This is the reinforced belt type. It has the same ~4 mm mesh opening like the F4012 but with stronger wires of 1,5 mm for higher mechanical impacts and improved shear resistance. It is mainly used in bigger ovens for improving the operational lifetime.

Because of the higher weight, increased energy needs, tougher requirements to the oven drive & support construction have to be considered.

For belt width of >1500 mm it is nearly a must, but often used also for belt width of 1000 & 1200 mm in longer ovens.

Some OEMs or endusers principally prefer to go for this more stable belt type, often without technical necessity.

The easy cleaning Z-belt F6014 (~Z48)

This is the belt type that gives brushes an easier job to clean. It has the highest ratio between wire diameter (1,4 mm) and mesh opening (~6 mm). So it is good for baking products containing great amounts of fat, grease or sugar.

The advantage of the F6014 is that it has the same weight as the standard F4012 (Z47). So no change in the heat management of the oven is necessary, if clients want to use it for cleaning reasons (provided the dough consistency allows it)

In many countries, where the “general taste” likes sweet and sugary products, often combined with a high amount of fat, this belt type became the winner over the last decade.

Many bakeries changed from F4012 to F6014 for its better cleaning characteristics.

The fine mesh Z-belt F2510 (~Z28)

This is the “filigree” belt with the smallest mesh opening (2,5 mm) and thinnest wire (1,0 mm). It has the lowest energy demand and can be an alternative for solid steel belts, so that the advantages of better heat circulation and easy maintenance of a mesh belt are given.

In some bakeries in the European Union this belt became the “one and only” belt used for its great flexibility with regard to the cookie or biscuit product baked.

With its sensitive mesh structure and edges, this belt should be used in smaller ovens with max. ~1200 mm width and shorter oven lengths.

The heavy weight Z-belt F4018 (~Z47RR)

This “double-reinforced” belt is comparatively new and has the biggest wire diameter possible of 1,8 mm in combination with a mesh opening of ~4 mm. So, with a weight of ~14,2 kg/sqm (which is practically double the weight of the standard F4012 (~Z47), an increased heat storage potential in the baking process is given, which allows tunnel ovens either to run faster and with higher temperatures or the use in conduction baking (of special type of crackers etc.)

Despite its high weight of ~14/sqm, the user can take advantage of improved air circulation compared to multiple spiral belts (like CB5 & CB3) and their often unnecessarily extremely heavy weights.

With this, the little “journey” through the world of baking belts and Z-belt comes to an end.

Currently the market is exciting. Because of its great variety in belt types and widths the rolled baking oven belt is getting more and more popular.

The tendency of the last years was to “think big” and build bigger and bigger ovens is still going on with keywords like: Jumbo oven, high speed baking and capacity increase.

On the other hand the number of users, realising the advantages of smaller oven units with widths up to ~1250 mm, is increasing. They say that the “logistics” in the production (i.e. sorting and packing) following the baking is much easier to handle with a lower risk of production breakdowns.

With regard to the tunnel oven manufacturers, the European “big players” went under the roof of even bigger groups. European newcomer OEMs took advantage of the transition periods involved with these processes and became quite popular with endusers in Europe, Africa and the Far East. South East Asian OEMs established themselves in their home and neighbouring markets and Indian producers seeking more and more and successfully for export markets.

The “quality gaps” between European big players, newcomer OEM and Asian producers are getting smaller and smaller.

All of them are more open now to look for new possibilities and alternatives with regard to the mesh belt media uses. Completely new products like Granola are now “discovered” to be baked on higher weight Z-belts.

For oven maintenance the topic of belt cleaning is getting more and more importance, partly because of increased consumer awareness or enforced by laws or regulations, not to forget the permanent “battle” for belt tracking, tensioning and support

But that should be different stories and articles to write ……

written by Peter Otten – STEINHAUS GmbH

Die ACHEMA findet vom 10.-14.06. 2024 in Frankfurt statt - und wir sind dabei! Sichern Sie sich jetzt Ihr kostenloses Ticket für die ACHEMA 2024!

More

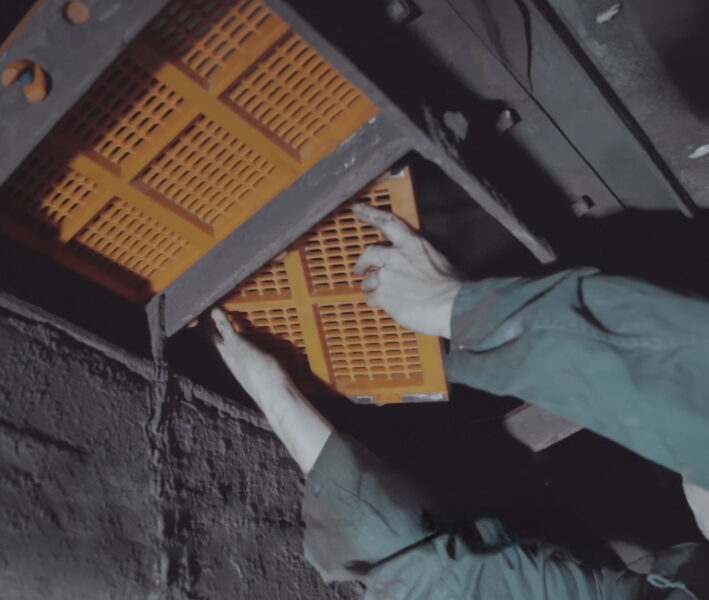

The STEINHAUS MLock is the world's first magnet-based system screen panel that is self-centering in all three dimensions.

More

Our 100 Years celebration with active and retired employees was great fun. Here is a little insight.

More

It's #throwbackthursday! Today with a 40 year old statement that is still true today.

"Whatever field you choose, with STEINHAUS you always make the right move".

STEINHAUS has always been one of the pioneers in the field of polyurethane screen panels.

With STEINHAUS MLock - the world's first self-centering magnet-based system screen, we are taking the next step.

Wir haben etwas zu feiern! Unseren 100. Geburtstag. 100 Jahre Familienunternehmen, 100 Jahre zuverlässige Qualitätsprodukte und kompetente fachliche Betreuung, 100 YEARS | TAILOR MADE

More

The STEINHAUS Green Drain screen cylinder - best results, even with high stress.

More

Our Brazilian customers and all interested parties from the food industry can now contact Mr. Celso Pires, another competent local contact.

More

OPTIMA Separator Cylinders are used, among other things, for the solid-liquid separation of slurry. Further applications can be found in biogas plants, slaughterhouses or in the production of green bedding.

More

Visit us. Talk to us. We look forward to seeing you!

More

Our wire belts are used in blasting plants for descaling, deburring and cleaning of castings and laser cut parts. The specifications of the belts can be individually adapted to your requirements.

More

When operating a tunnel oven the issue of proper belt tracking will always be on the agenda and of greatest importance for a good, smooth and trouble free oven operation.

More