Wide range of options

STEINHAUS polyurethane screens have for many years been regarded as the epitome of reliability and a long service life. We offer screen panels in the widest possible range of designs.

More

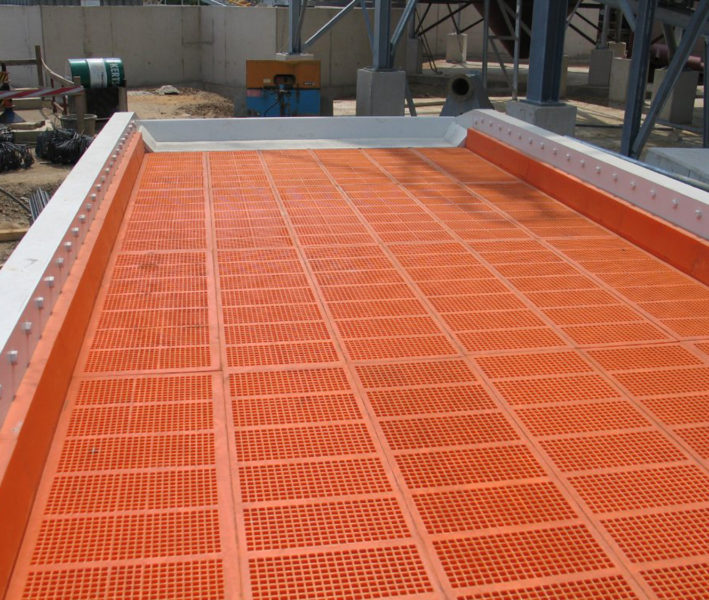

KOMBIPLAST – the Classic

KOMBIPLAST® has been our tried and tested system screen panel since 1976. It is attached to the screening machine by means of an expansion anchor system without an adapter strip.

Especially in the steel industry, where highly wear-resistant sheets with a thickness of up to 15 mm are used, they usually rely on this system, which has stood the test of time for more than 40 years.

Components are fitted into the support structure effortlessly. The fixing pins, which connect the screen panel with the screening machine so that there is no vibration, are then driven in. To remove a screen panel, the inner section of the fixing pin can be knocked out with a punch. The expansion anchor will thus be released and the screen panel can be demounted without any effort.

An L-profile with a drill hole every 150 mm (or, for particularly heavy uses, every 75 mm) is used as a support structure.

Side fastening is made by a traditional method with a wedge strip and wedges. Alternatively, narrow edge strips can be fitted using the push-fit system; this means that when changing the screens there is no need to demount the wedge strips.

STEINHAUS polyurethane screens have for many years been regarded as the epitome of reliability and a long service life. We offer screen panels in the widest possible range of designs.

More

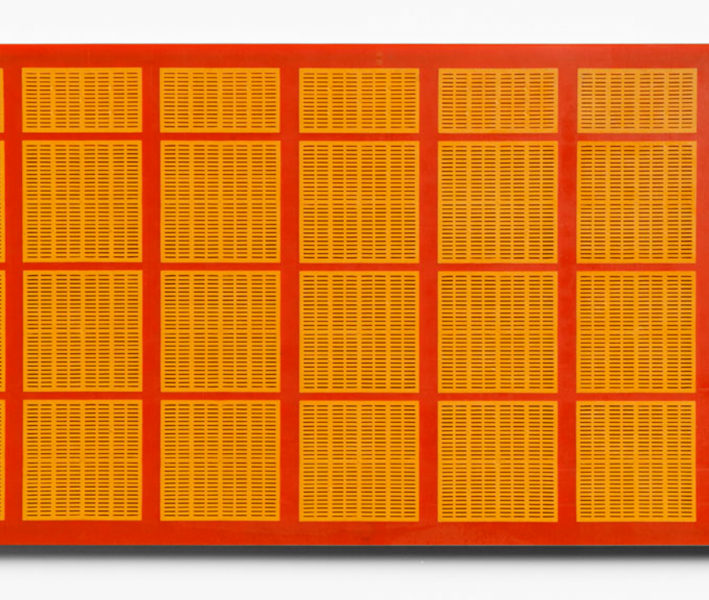

UNI 2000 system screen panels made from highly wear-resistant polyurethane are standardised modules using the modular design principle with component dimensions covering widths of 100 - 400 mm and lengths of up to 1000 mm.

More

Polyurethane plain screens are bolted to the screening machine or connected by means of wedges so that there is no vibration.

More