Perforated Plates

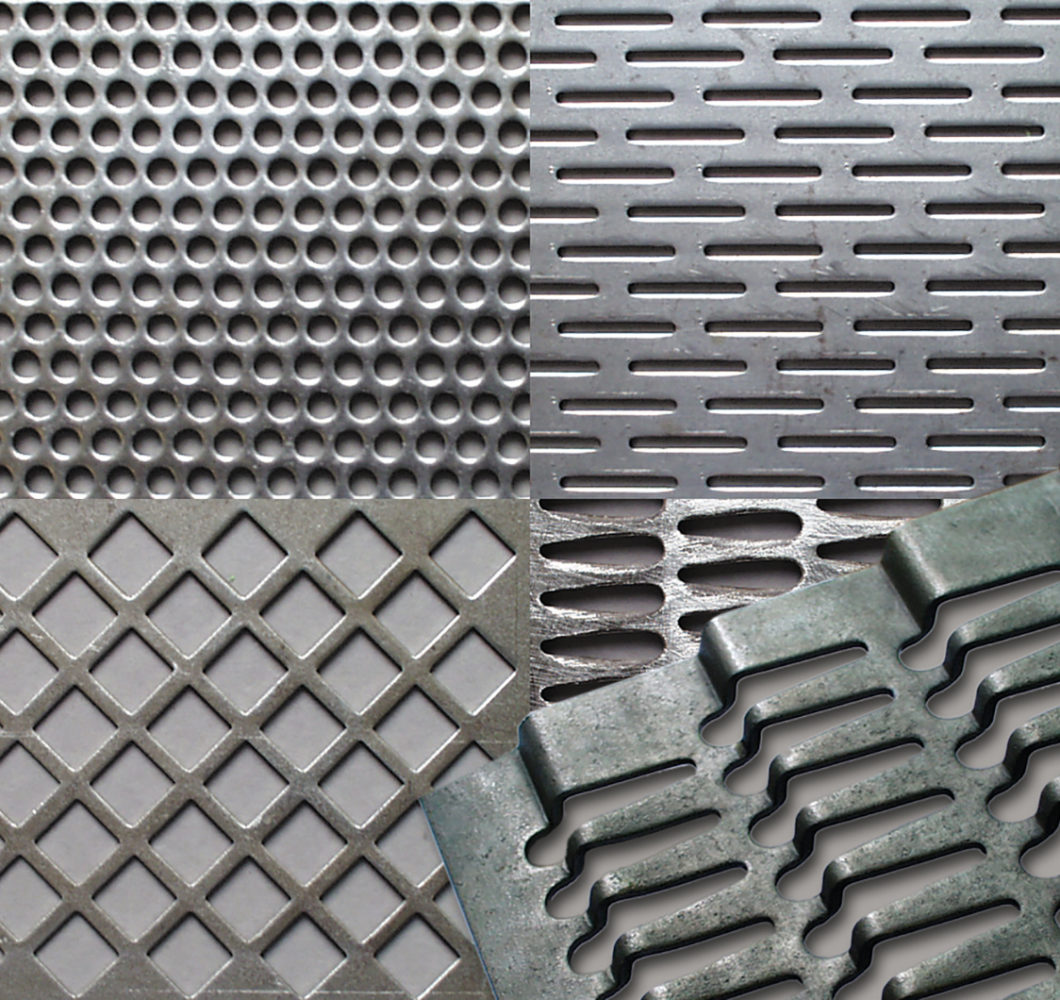

Perforated sheets are manufactured with matching apertures at regular intervals by means of punching, drilling or milling. Any material, e.g. steel, stainless steel, copper, aluminium or plastic, can be perforated in virtually any technically feasible geometry.

As a standard value, the hole diameter and the bridge width should be no smaller than the thickness of the material used. The perforated sheets can be manufactured with or without an unperforated edge.

Punched perforated sheets always have a slight conical widening on the punch outlet side, causing a punching burr. Burr fineness can only be ensured by additional aftertreatment.

Particularly in the chemical and foodstuff industries, micro-perforated plates have made a significant contribution to solving difficult separation problems, e.g. with centrifuges. They now supplement fine-screen plates made from punch-perforated plates or wire mesh for separating processes that call for the highest precision and optimum throughput.

STEINHAUS supplies micro-perforated plates in the form of sheets and as segments of all kinds in dimensions of up to 1000 x 1000 mm, and thicknesses of 0.07 to 0.75 mm.

The surfaces of micro-perforated plates can, if required, be finished in hard chrome.

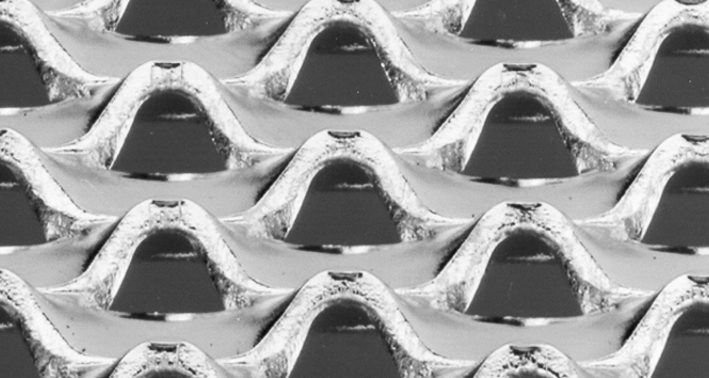

CONIDUR® perforated sheets

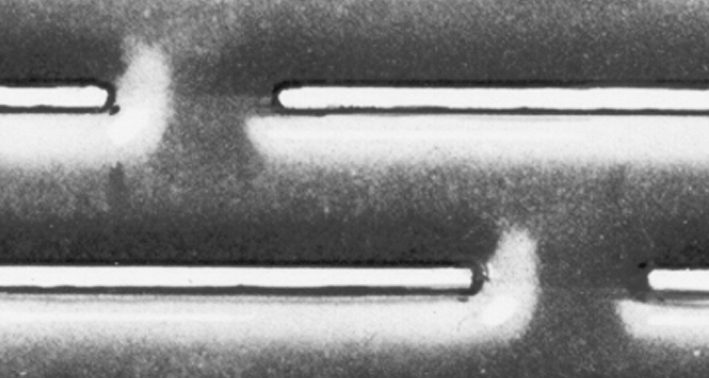

CONIDUR® perforated sheets are sheets with a special hole shape.

In contrast to the usual round hole shape with even hole sides in the through-pass direction, the perforations in the CONIDUR® perforated sheets are formed in a more triangular to half-elliptical shape, which means that they have conical openings placed at an angle in the through-pass direction.

The upper and lower side of the CONIDUR® perforated sheets differ in design.

Depending on the design of the perforation, one side (normally the side facing the product) is scaly and raw, with the other side being smooth.

The special manufacturing process enables the finest perforations in starting material sheets whose thickness may be a multiple of the hole width.

CONIDUR® perforated sheets are cold-worked during manufacture. This makes them very wear-resistant, a feature that can be further improved with the appropriate aftertreatment.

Depending on the specification, CONIDUR® perforated sheets can be processed into moulded products.

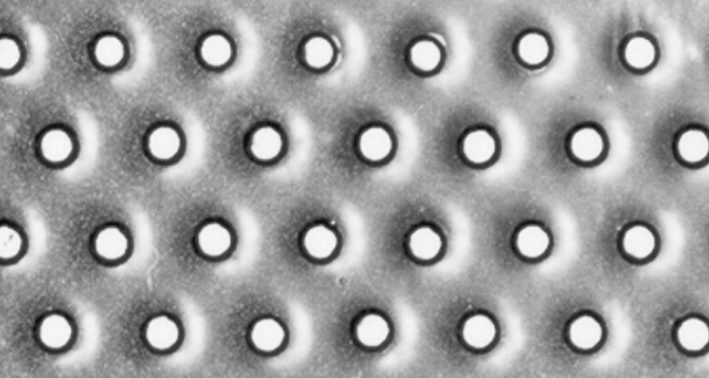

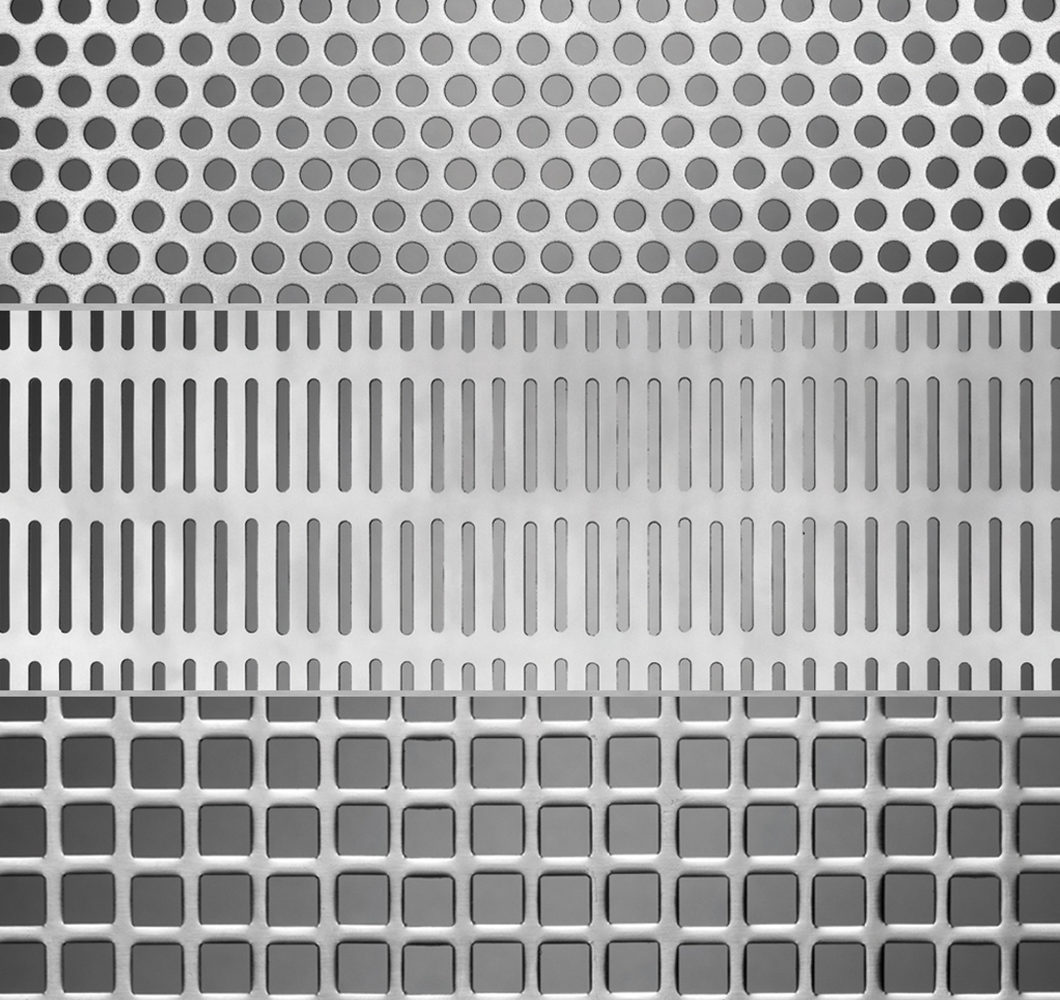

Electroformed sheets

Particularly in the chemical and foodstuff industries, electroformed micro-perforated plates have made a significant contribution to solving difficult separation problems, e.g. with centrifuges. They now supplement fine-screen plates made from punch-perforated sheets or wire mesh for separating processes that call for the highest precision and optimum throughput.

In recent years micro-perforated plates manufactured from pure nickel in an electroplating process have found application in countless branches of industry.

Design

- Perforated plates with round and square perforations and with slotted and special perforations.

- Perforated plates manufactured by electroplating, with a smooth upper surface on the working side and with perforations that widen conically in the through-pass direction.

- Smallest hole widths from 0.04 mm as a round or a slotted perforation.

- Special hole shapes on request.

Material

Soft or hard nickel with bright or very bright surface

Application

As filters, screen/centrifuge linings, printing stencils, separators for dust, water, oil, petrol, etc.

The advantages

- The hole shape can be adjusted to suit every intended use.

- The surface is completely smooth on the working side.

- High degree of resistance to corrosion, acid and abrasion. (This can be increased still further with the application of a layer of hard chrome).

- Holes that widen conically in the through-pass direction guarantee the greatest possible freedom from clogging.

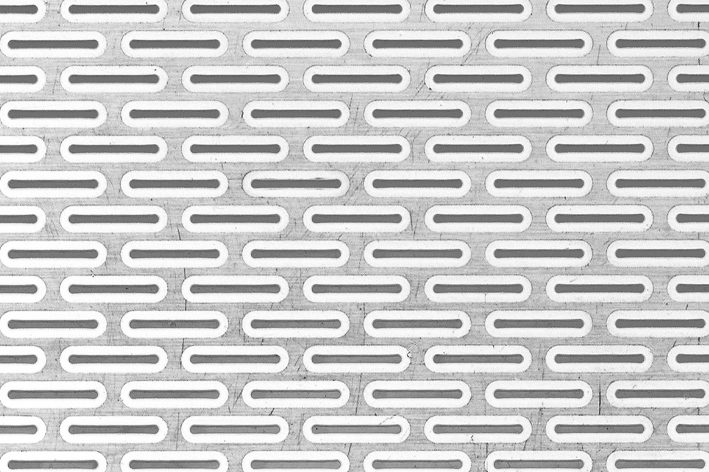

Drilled perforated sheets

We supply drilled perforated sheets with varying hole cross-section shapes in high-precision design.

Material:

Commonly used chrome steels and other machinable materials

Design:

Hole diameters from 0.7 to 10 mm and plate thicknesses from 2.0 to 10 mm

Hole configuration:

In straight rows (rectangular or square), diagonally staggered, in staggered equilateral triangles, in staggered isosceles triangles