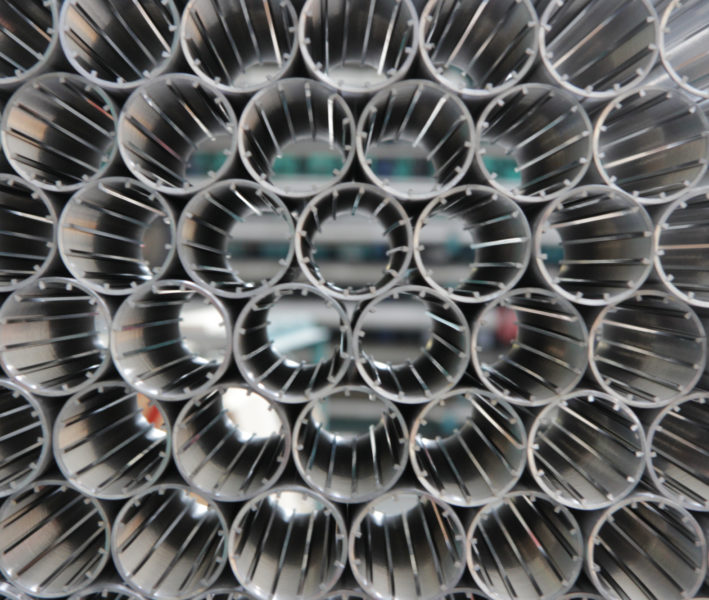

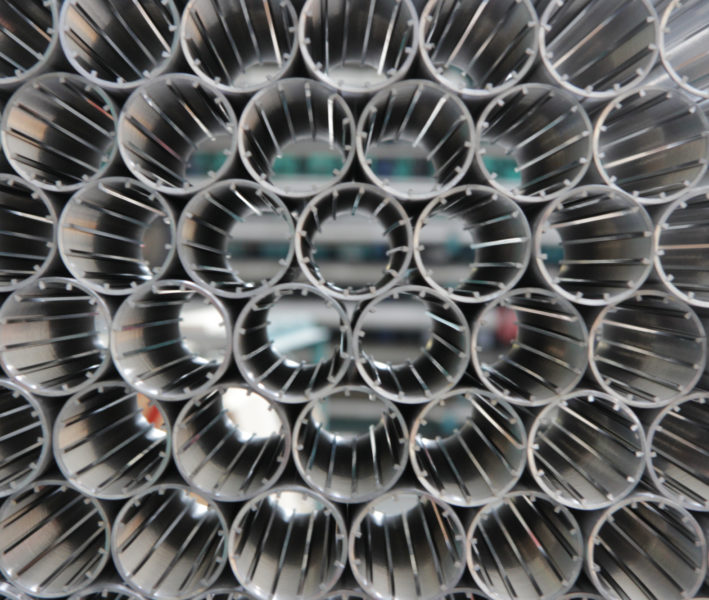

High Precision Filter Tubes

OPTIMA spiral cylinders are produced with diameters up to 1,022 mm. OPTIMA precision filters, on the other hand, cover a range from 23 mm to 305 mm.

More

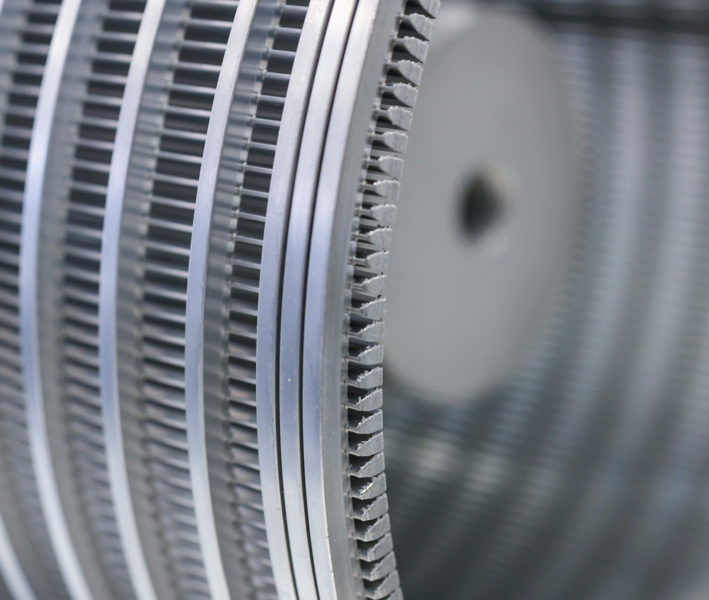

OPTIMA slotted wedge wire screens are used mainly for solids/liquids separation in a virtually unlimited range of situations. These can be dewatering pipes, filter cartridges, screen baskets, filter drums or centrifuge screens.

Plain or bent wedge wire panels are used in areas such as:

The available OPTIMA slotted wedge wire screens can be produced from the finest profile wires to achieve the highest possible open screen area right through to very large, sturdy designs to withstand high mechanical impacts. The different profile dimensions can also be supplied in various designs, some of which have been patented.

Flat OPTIMA screens are machine-made using a flat welding process. In addition to this procedure it is possible, using our round winding machine, to produce a welded wedge wire screen cylinder which is then flattened by re-rolling.

Looped wedge wire screen elements are looped and pressed wedge wire panels made of profiled longitudinal wires and round cross bars.

Präzissa looped wedge wire screens are preferred by the confectionery industry because they can have a conical slot width.

These screen grids or screen rakes consist of specially shaped profiles with round-rod crossbars. Spacer sleeves or wire rings secure the required slot width. STABO grids are used for dewatering, as protective cover grids, or as coarse or fine rakes in wastewater management.

Reinforcement with various types of steel and execution according to customer requirements. We will manufacture what you need, be it side rails for clamping or flange variants for bolting. For smaller dimensions, plain sieve panels are often supplied as one piece ready-bolted for installation, whereas for larger objects they are made in several individual segments. These individual segments can be trapezoidal, triangular or conical, and can optionally be supplied with or without a maintenance flap.

Wedge wire panels with shape-retaining cross bars and matching edge strips that snap into 2-fold notched intermediate strips made of polyurethane.

OPTIMA spiral cylinders are produced with diameters up to 1,022 mm. OPTIMA precision filters, on the other hand, cover a range from 23 mm to 305 mm.

More

The successful separation of materials into different phases, largely in the field of solids/liquids separation, is a top-priority challenge in many industrial sectors.

More

OPTIMA slotted screen baskets are produced using a qualitatively demanding process to give a high degree of fitting accuracy for the best possible separating performance.

More