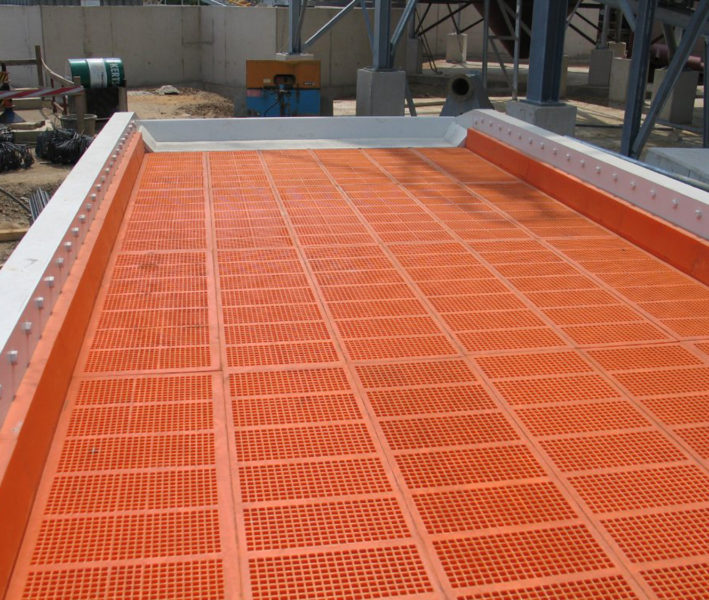

KOMBIPLAST® modular screens

KOMBIPLAST® modular screen panels are made from highly wear-resistant polyurethane and can be produced using the modular design principle as a screen or a solid component.

More

STEINHAUS polyurethane screens have for many years been regarded as the epitome of reliability and a long service life.

In 1968 STEINHAUS GmbH introduced the first industrially produced polyurethane screens to the public. These were followed in 1976 by a further global innovation, the first modular screen panel.

Wherever technically possible, elastic screens made from polyurethane have replaced wire screens.

The demands made on a screen panel vary considerably according to application: If you need an extremely large screen area, choose our

HE (high efficiency) series. RG (regular) is our standard series, while our LL (long-life) series is exceptionally robust.

We offer the optimum screen for every purpose with different series frequently being combined on a single screening machine.

Steinhaus always uses polyurethanes with the best possible wear-resistant properties supplied by brand manufacturers. The sophisticated production system enables precise and economical production.

There are several hundred different hole widths in different hole shapes available for polyurethane screens. At present we can manufacture slit perforations from 0.1 x 5.6 mm to 15 x 110 mm and square perforations from 0.8 mm to 150 mm.

Depending on the material to be screened and the parameters of the screening machine, softer screens reliably help to prevent clogging with jamming particles. For this we offer our polyurethanes with the following degrees of hardness in the perforated areas: 35, 45, 65 or 85 Shore A.

The noise-damping properties of polyurethane reduce noise emission. Official environmental and occupational health and safety requirements can thus be met more easily.

Polyurethanes can normally be used at temperatures of up to approx. 80 °C. We offer special products that can be used up to a screened material temperature of 120 °C and even up to 160 °C.

For products that are very hard to screen we recommend our polyurethane whipping screens. A thin elastic screen mat is fastened to a frame so as to be able to vibrate freely. This can prevent deposits of sticky screened material from building up.

Wear-resistant perforated sheets, welded wedge wire screens, wire mesh, harp-mesh screens or even bar screens – we can make any screen you require as a modular screen. The uniform module size enables all screen types to be combined.

Our TeePee screens dewater in the third dimension. TeePee screens have a considerably larger open screen area. The tips protrude into the material to be dewatered, so that the dewatering characteristics, especially those of hard-to-drain products, are massively improved.

KOMBIPLAST® modular screen panels are made from highly wear-resistant polyurethane and can be produced using the modular design principle as a screen or a solid component.

More

UNI 2000 system screen panels made from highly wear-resistant polyurethane are standardised modules using the modular design principle with component dimensions covering widths of 100 - 400 mm and lengths of up to 1000 mm.

More

Screens made from highly wear-resistant rubber find wide-ranging application today in the mining industry.

More