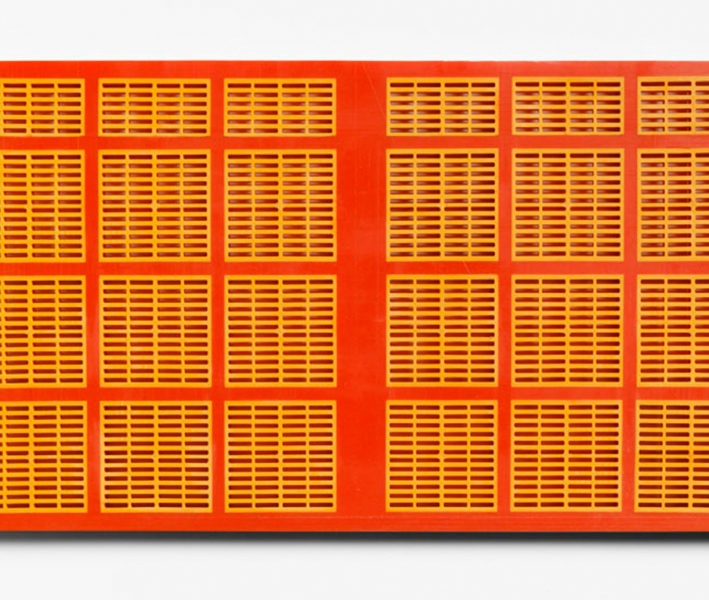

Wire cloth, standard design

Screen panel with sound performance characteristics.

More

Wherever technically possible, screens made from polyurethane have almost completely replaced steel screens.

Nevertheless, screens made from steel are the screening medium of choice for many applications and are not yet to be replaced.

One significant advantage of wire screens is the larger open screen area as compared with polyurethane screens. For instance, if it is necessary to achieve a very high throughput with a small screening machine, wire screens could be the solution. Although it is true that wire screens are not so cost-efficient because of their shorter service life, they nevertheless have many uses, as for example in mobile processing machines.

As the screening material falls onto narrow, hard wire, cohesive material to be screened breaks apart very easily. When dry screening sticky material, it makes sense to use wire screens.

The positive effect of self-cleaning is perfected with our self-cleaning wire cloths.

Mesh-like screen panels

For screening damp, hard-to-screen material with predominantly round or cubic particle shapes on screening machines and other screening equipment.

To be used for inherently moist sand, lime sandstone, marl, magnesite, dolomite, olivine, chamotte, phosphate, fertiliser, salts, plastic granules, etc.

The self-cleaning effect

HARFEN screen panels achieve self-cleaning by the knocking effect of the sieved material and the natural oscillation and cutting effect of the screening wires. Preferably, the feed contains approx. 10% “knocking particles” of a size approx. 5 times the width of the separation size. Screening wires made of chrome nickel steel, with their permanently smooth surface and polyurethane cross-connections, will support the self-cleaning effect. If the material is very hard to screen and no “knocking particles” are available, we recommend a ball-tapping device.

HARFEN screen panels must be tensioned in the direction of the longitudinal wires, as otherwise they will not be able to demonstrate their good functional features, such as high slot precision and effective self-cleaning. For material that is hard to screen, such as sand with high clay content, we recommend thin-wired HARFEN. Their cutting effect reduces potential bridge formation. Thick-wired HARFEN and HARFEN with flexible cross-connections made of highly wear-resistant polyurethane improve operating times and reduce operating costs. If oversized oblong particles are permissible in the throughput, it is possible to use HARFEN for poorer particle shapes as well. HARFEN have a large free screen area that significantly increases the throughput rate of the screening machine.

HARFEN screen panels are mesh-like panels with round wires and slot-shaped screening apertures. To properly attach the harp-mesh screens to the screening machine a tensioning device is required. For screening machines with a flat screening deck we supply changeable tensioning frames. HARFEN comes in 3 designs:

HARFE-WS

has corrugated longitudinal wires with cross-connections in any interval size to suit the support structure of the screening machine, as per the adjacent drawing.

HARFE-G

has straight longitudinal wires, with cross-connections at uniform, fixed intervals as per the table. HARFE-G is particularly suitable for screening hygroscopic material with a high adhesion tendency, e.g. artificial fertiliser. The smooth screening wires – preferably made of stainless steel – can be cleaned without a problem.

HARFE-G-PLAST

has straight longitudinal wires with elastic polyurethane cross-connections for highly abrasive material to be screened and for applications where the flexible cross-connection is intended to prevent bridge formation. As with the HARFE-WS, the cross-connection intervals should match the traverse intervals of the screening machine. A corrugated longitudinal wire, positioned at intervals, serves to fix the cross-connections.

Mesh-like screen panels

TRIA and SERPENTI screen panels, due to their design, have an excellent self-cleaning effect as a result of the movement of the screening wires relative to each other. This is principally due to the coarse-grained material to be screened, i.e. the knocking particles. This means that approx. 10% of the material to be screened should be at least 5 times as large as the screening apertures. The use of non-rusting steels with a smooth surface further improves the self-cleaning effect.

In contrast to harp-mesh screens with slot-shaped screening apertures, TRIA and SERPENTI achieve good screening results, even with oblong particles, because of their horizontal corrugated screening wires.

SERPENTI screen panels’ apertures are almost square and those of the TRIA screen panels are almost triangular.

Fields of application:

Because of their good self-cleaning effect, these fabric-like screen panels are successfully used:

for ores, pellets, sinter, raw coal, washed coal, coke, gravel, grit, sand and gravel, limestone, cement clinker, etc.

TRIAPLAST with elastic polyurethane cross-connections further improves the self-cleaning effect. The good wear-resistance of the polyurethane lengthens the overall service life of the screen panel. Polyurethane cross-connections can be used with screened material temperatures up to a maximum of 80 °C.

TRIA and SERPENTI screen panels with cross-connections made from steel wires or polyurethane are only to be used as tension screen fields on screening machines with a tensioning device.

TRIA® harp-mesh screens

Screen panels made from alternate straight and horizontal corrugated round wires with interwoven cross-connections from round wire with 3 x 3 = 9 cross wires per layer.

TRIAPLAST® harp-mesh screens

Screen panels made from alternate straight and horizontal corrugated round wires with elastic cross-connections from highly wear-resistant polyurethane.

SERPENTI harp-mesh screens

Screen panels made from horizontal corrugated round wires with interwoven cross-connections made from round wire with 4 x 2 = 8 cross wires per layer.

SERPENTIPLAST

As with TRIAPLAST we can, if required, equip our SERPENTI screen panels with polyurethane cross-connections instead of steel cross-connections.

Screen panel attachments

Cross-connection pitches for tension screen fields

With TRIA and SERPENTI tension screen fields the pitches of the cross-connections of the screen panel are to be matched to the traverse intervals of the screening machine.

This guarantees optimal natural oscillation of the screening wires between the cross-connections and therefore a good self-cleaning effect. In addition, this avoids premature wear to the screening wires at the contact points. TRIA and SERPENTI screen fields can only be tensioned in the direction of the corrugated or straight screening wires respectively.

Screen panel with sound performance characteristics.

More

Polyurethane tension screens are connected to the screening machine, either crosswise or lengthwise, by means of a clamping device.

More

STEINHAUS polyurethane screens have for many years been regarded as the epitome of reliability and a long service life. We offer screen panels in the widest possible range of designs.

More