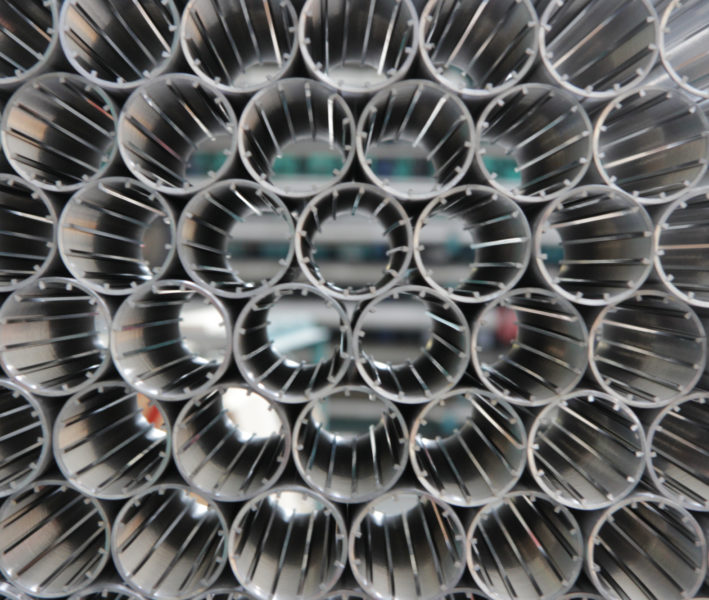

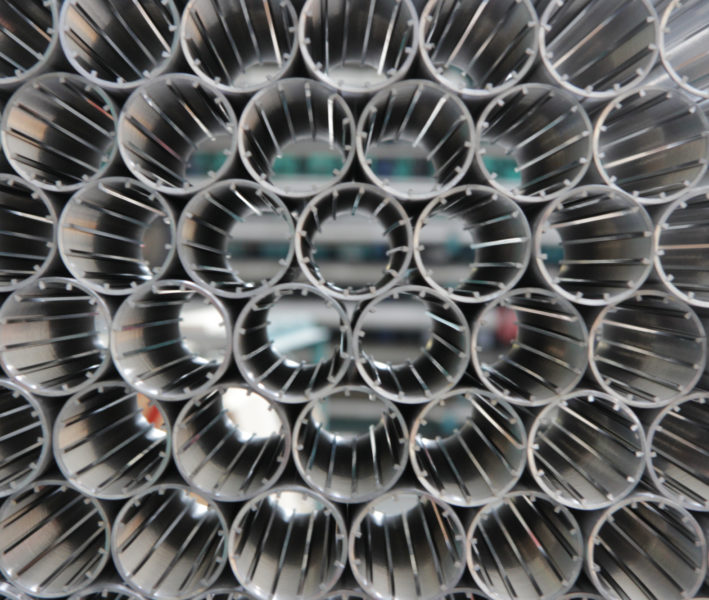

High Precision Filter Tubes

OPTIMA spiral cylinders are produced with diameters up to 1,022 mm. OPTIMA precision filters, on the other hand, cover a range from 23 mm to 305 mm.

More

Wir fertigen Formfilter in allen möglichen Formen, Geometrien und Blechdicken nach individuellen Kundenwünschen. Von Prototypen bis hin zur Großserie und aus allen gängigen Materialien.

Für eine betriebssichere Filtration werden die Verbindungsverfahren je nach Verwendungszweck bzw. Ihren Vorgaben entsprechend ausgewählt.

Formfilter von STEINHAUS gibt es in allen technisch herstellbaren Formen. Zum Beispiel als Filterscheiben (rund, rechteckig, quadratisch), als Zylinder, Kegel oder als Halbschalen, uvm. Wir liefern fertige Filterelemente, Filterplatten und Filterkörbe. Unsere Formfilter werden mit hoher Präzision kundenspezifisch nach Zeichnung gefertigt, egal ob stumpf-, rollen- oder punktgeschweißt, weich- oder hartgelötet, gebördelt, gezogen, gedrückt oder gepresst.

During the initial commissioning of an installation, start-up filters serve to remove production residues in the pipeline and apparatus construction, such as slags and electrode residues that have found their way into the system during assembly and welding work. Damage to downstream components is thus prevented and the risk of costly operational disruptions markedly reduced.

Start-up filters comprise a support element made from perforated sheet or wire mesh, onto which the actual fine mesh filter cloth is fitted, plus a flanged ring for attaching in the pipeline. The size of the mesh holes in the filter mesh depends on the requirements.

All commonly obtainable steel qualities are used as materials for filter cloths, support elements and flanged rings.

Dual-cone start-up filters (double hat-type screen)

If the fitting length available is insufficient to accommodate a single-cone start-up filter with the required filter surface, it is usually possible to fit a dual-cone start-up filter with a reduced construction height and the same filter surface.

Filter cartridges are used, for example, for cleaning and regenerating cutting oils for machine tools. These filter cartridges, which work on the principle of pre-coat filtration, enable a high throughput in the smallest possible space. Their robust construction means that they can also be used without a problem at high operating pressures. Alternatively, cartridges made of spirally wound triangular wire can be employed. These normally have a slot width of 30 µm or 60 µm.

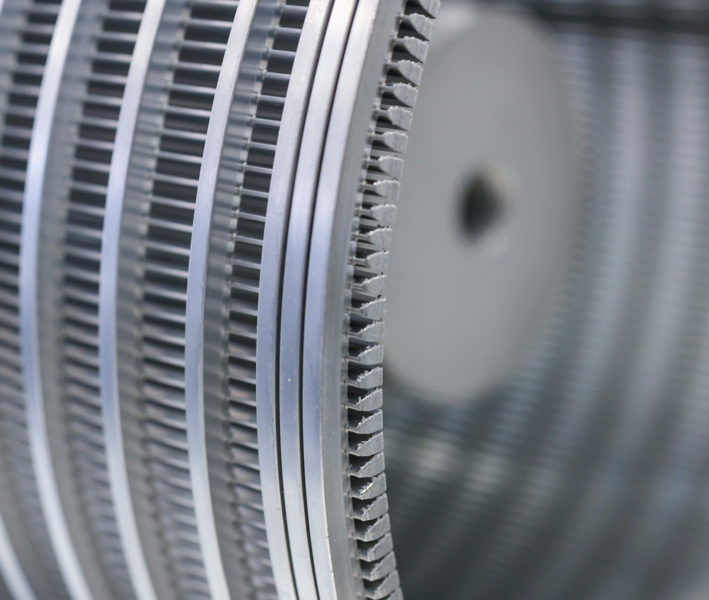

OPTIMA damping screens consist of 8 mm thick, cylindrically drilled perforated sheets that are bent and then welded. This production process allows for a large free filter surface with compact screen dimensions. The screens are made of highly corrosion-resistant stainless steel and are used principally in power plant technology, where they protect valves and steam turbines against damage from contamination and foreign objects.

OPTIMA filter discs consist of different wire cloths and can be supplied with or without side rails. They are used in industrial applications, in all shapes and dimensions, mainly as a protection screen or in screen changing equipment for filtration of plastic melts, for instance. The discs can comprise one or more filter layers. The potential combination is governed by the specific use and the filter fineness required or by the customer specifications.

OPTIMA spiral cylinders are produced with diameters up to 1,022 mm. OPTIMA precision filters, on the other hand, cover a range from 23 mm to 305 mm.

More

The successful separation of materials into different phases, largely in the field of solids/liquids separation, is a top-priority challenge in many industrial sectors.

More